Imishini yokushisela i-laseriyindlela yokushisela ephumelelayo nenembile esebenzisa ugongolo lwelaser olunamandla amakhulu njengomthombo wokushisa.I-Laser Welding ingenye yezinto ezibalulekile ekusetshenzisweni kobuchwepheshe bokucubungula izinto ze-laser.Ngawo-1970, yayisetshenziselwa kakhulu ukushisela izinto ezinezindonga ezincane kanye nokushisela okunesivinini esiphansi.Inqubo yokushisela iwuhlobo lwe-thermal conduction, okungukuthi, ingaphezulu le-workpiece lishiswa ngemisebe ye-laser, futhi ukushisa okungaphezulu kusakazwa ngaphakathi ngokuqhutshwa kwe-thermal.Ngokulawula ububanzi, amandla, amandla aphezulu kanye nemvamisa yokuphindaphinda kwe-laser pulse namanye amapharamitha ukuze kuncibilike ucezu lokusebenza bese kwakha ichibi elithile elincibilikisiwe.Ngenxa yezinzuzo zayo eziyingqayizivele, isetshenziswe ngempumelelo ekushiseleni okunembayo kwezingxenye ezincane nezincane.

一、Izici zokushisela

Kungokwe-fusion welding, esebenzisa i-laser beam njengomthombo wamandla ukuze kube nomthelela ekuhlanganyeleni kokushisela.

I-laser beam ingaqondiswa into ekhanyayo eyisicaba, njengesibuko, bese ikhonjiswe kumthungo we-weld ngento yokugxila ekhanyayo noma isibuko.

Ukushisela nge-laser kuwukushisela okungathinteki, akukho ngcindezi edingekayo ngesikhathi sokusebenza, kodwa igesi ye-inert iyadingeka ukuze kuvinjelwe i-oxidation yechibi elincibilikisiwe, futhi i-filler metal isetshenziswa ngezikhathi ezithile.

I-laser welding ingahlanganiswa ne-MIG welding ukwakha i-laser MIG composite welding ukuze kuzuzwe ukushisela okukhulu kokungena, futhi okokufaka ukushisa kuncishiswe kakhulu uma kuqhathaniswa nokushisela kwe-MIG.

二、Isimiso sokusebenza somshini wokushisela isikhunta

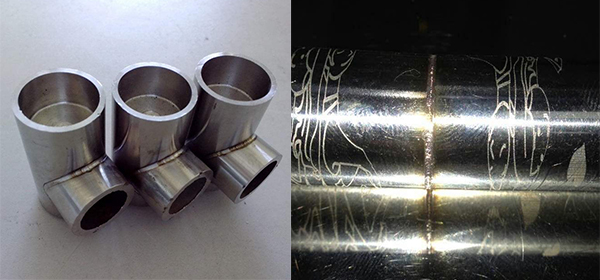

Umshini we-mold laser welding nawo uyigatsha leumshini wokushisela we-laser, ngakho-ke isimiso sokusebenza siwukusebenzisa ama-laser pulses aphezulu ukuze kushise izinto endaweni encane.Amandla emisebe ye-laser ahlakazeka entweni ngokuqhutshwa kokushisa, futhi impahla iyancibilika futhi yakheke.i-melt pool ethile.Iwuhlobo olusha lwendlela yokushisela, ngokuyinhloko yokushisela izinto ezinodonga oluncane kanye nezingxenye ezinembayo, futhi ingakwazi ukubona ukushisela indawo, ukushisela izinqe, ukuthunga ukuthunga, ukubeka uphawu, njll. Ukuguqulwa okuncane, isivinini sokushisela okusheshayo, ukushisela okubushelelezi nokuhle. umthungo, asikho isidingo noma ukwelashwa okulula ngemva kokushisela, ikhwalithi ephezulu yokushisela i-seam, azikho izimbotshana, ukulawula okunembile, indawo encane yokugxila, ukunemba kokuma okuphezulu, kanye ne-automation elula.Imishini yokushisela i-laser enamandla amakhulu iye yasungulwa, futhi izitayela ezihlukahlukene zemishini yokushisela i-laser nokulungiswa kungabonakala ezintweni eziwugqinsi.

Isampula:

三、 Izici ze-mold laser welding

Umshini wokushisela we-laser wesikhunta wamukela isibonisi sesikrini esikhulu se-LCD Chinese esibonakalayo, okwenza kube lula ku-opharetha ukufunda nokusebenza.Izisetshenziswa futhi zamukela umsebenzi wokuhlelwa kwefonti ukuze kutholwe umsebenzi wemodi eminingi, efanele ukulungiswa kwesikhunta sezinto eziningi.Akuyona nje indawo ethintekile ukushisa encane, izinga le-oxidation liphansi, kodwa futhi ngeke kube nama-blister, ama-pores nezinye izenzakalo.Ngemva kokuba isikhunta silungisiwe, umphumela wokulungisa uwukufeza ukungalingani ekuhlanganyeleni, futhi ngeke kubangele ukubola kwesikhunta.

四、Ubuchwepheshe bokucushwa nokucubungula

1.Isikhuntaumshini wokushisela we-laserkufanele isebenzise isibonakhulu esingu-10X noma esingu-15X ukuze iqaphe ukusebenza.

2. Ukunikezwa kwamandla komshini we-mold laser welding kungasebenzisa umsebenzi oguquguqukayo we-waveform, ofanele ukushiselwa kwezinto ezihlukene.Okufana: insimbi yokufa, insimbi engagqwali, ithusi le-beryllium, i-aluminium, njll.

3. Uhlelo lwe-CCD (uhlelo lwekhamera) lungasetshenziselwa ukuqapha, umsebenzi uthi: ngaphezu kokuthi opharetha ebuka ngesibonakhulu, abangewona opharetha bangabuka yonke inqubo yokushisela ngesikrini sokubonisa sesistimu yekhamera, le divayisi kunenzuzo kokungasebenzisi Ukuqeqeshwa kobuchwepheshe kwabasebenzi kanye nemibukiso yemibukiso kubambe iqhaza elihle ekukhuthazeni ubuchwepheshe bokushisela nge-laser.

4. Ingakwazi ukuncibilikisa izintambo zokushisela ezinobubanzi obuhlukene, ukusuka ku-0.2 kuya ku-0.8 ububanzi.

5. Umshini wokushisela we-laser wesikhunta kufanele uvikelwe igesi ye-argon, futhi uhlelo kufanele lusethwe ukuze lukhiphe igesi ye-argon kuqala bese kuba i-laser ukuvimbela i-oxidation ye-laser pulsed yokuqala ngesikhathi sokucubungula okuqhubekayo.

6. Uma isikhunta sishiselwe nge-laser, into evame kakhulu ukuthi kunezimpawu zokuluma ezungeze ingxenye yokushisela.Kuyadingeka ukusebenzisa indlela ye-laser air punching ukumboza izinguquko ezingase zidale izimpawu zokulunywa ukuze kuvinjelwe ukwenzeka kwezimpawu zokulunywa.Kwanele ukuthi indawo yokukhanya idlula umkhawulo wesikhundla sokushisela ngo-0.1mm.

Isikhathi sokuthumela: Jun-12-2023