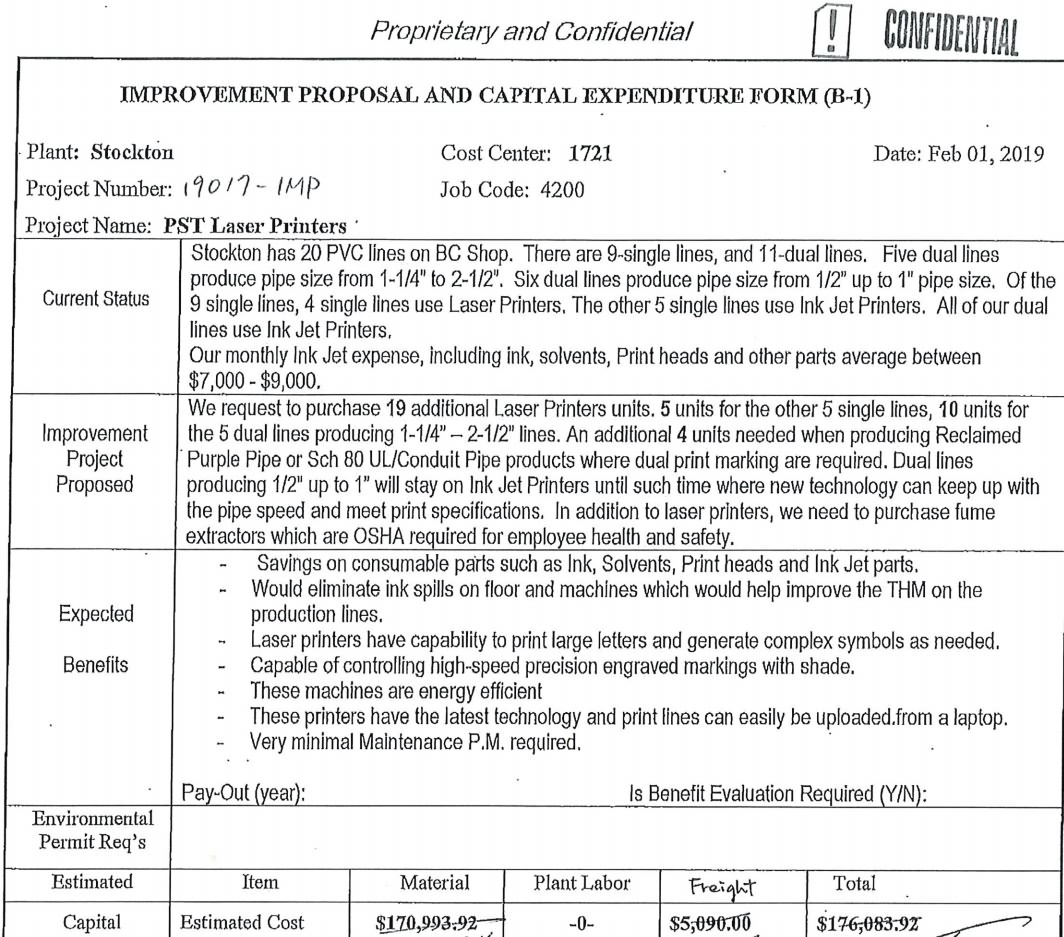

Umshini Wokumaka weLaser wePipe

Ukufakwa kwamapayipi kuyingxenye ebaluleke kakhulu embonini yezinto zokwakha.Ipayipi ngalinye linekhodi kamazisi ukuze lihlolwe futhi lilandelelwe nganoma yisiphi isikhathi, nganoma yisiphi isikhathi.Izinto zamapayipi endaweni ngayinye yokwakha ziqinisekisiwe ukuthi ziyiqiniso.Ukuhlonza okunjalo okuhlala njalo kudinga imicu yokubona.Umshini wokumaka we-laser usuqediwe.Ekuqaleni, abakhiqizi abaningi babesebenzisa imishini ye-inkjet ukumaka amapayipi, futhi manje imishini yokumaka i-fiber laser kancane kancane ithatha indawo yamaphrinta e-inkjet.

Kungani umshini wokumaka we-laser ushintsha umshini we-inkjet?

Izimiso zokusebenza zemishini yokumaka nge-laser namaphrinta e-inkjet zihluke kakhulu, njengezimoto ezisebenza ngogesi ezintsha kanye nezimoto zendabuko zikaphethiloli.Umgomo wokusebenza womshini wokumaka we-laser ukhishwa umthombo wokukhanya we-laser.Ngemuva kokuthi uhlelo lwe-polarizer lushile endaweni yomkhiqizo (ukusabela ngokomzimba namakhemikhali), imikhondo izosala.Inezici zokuvikela imvelo okuluhlaza, ukusebenza okuhle kokulwa nomgunyathi, okungaphambanisi, okungasetshenzisiwe, ukusebenzisa isikhathi eside, ukusebenza kwezindleko eziphezulu, nokonga izindleko.Awekho amakhemikhali ayingozi afana noyinki abandakanyekayo ohlelweni lokusebenzisa.

Umgomo wokusebenza wephrinta ukuthi isiteshi sikayinki silawulwa yisekethe.Ngemva kokushaja nokuchezuka kwe-voltage ephezulu, ulayini weyinki okhishwe emlonyeni wenza izinhlamvu ebusweni bomkhiqizo.Idinga izinto ezisetshenziswayo ezifana noyinki, isincibilikisi, ne-ejenti yokuhlanza, futhi izindleko zokusebenzisa ziphezulu.Idinga ukunakekelwa ngesikhathi isetshenziswa, ingcolisa imvelo, futhi ayinabungani nendawo ezungezile.Ungabheka futhi uqhathanise lezi zithombe ezimbili ezilandelayo:

Umshini Wokumaka we-Laser

Iphrinta ye-laser umshini wokumaka we-laser, osebenzisa ama-laser ahlukene ukuze ushaye isigxobo se-laser ebusweni bezinto ezihlukahlukene.Izinto ezingaphezulu zishintshwa ngokomzimba noma ngokwekhemikhali ngokusebenzisa amandla okukhanya, ngaleyo ndlela kuqoshwe amaphethini, izimpawu zokuthengisa nemibhalo.Imishini yokumaka ilogo.

Imishini yokumaka i-laser evamile ihlanganisa: umshini wokumaka we-fiber laser, umshini wokumaka we-carbon dioxide laser, umshini wokumaka we-ultraviolet laser;Phakathi kwazo, umshini wokumaka we-fiber laser kanye nomshini wokumaka we-UV laser ulungele amapayipi.

Umshini wokumaka we-fiber laser kanye nomshini wokumaka we-UV laser usetshenziselwa amapayipi enziwe nge-PVC, UPVC, CPVC, PE, HDPE, PP, PPR, PB, ABS nezinye izinto.

Izinto ze-PVC ezifaneleka kakhulu ezimakwe nge-fiber laser.

Izinto ze-PE ezifaneleke kakhulu ezimakwe ngelaser ye-UV.

Izinzuzo zomshini wokumaka we-laser:

1. Akukho okusebenzisekayo, impilo ende yesevisi kanye nezindleko eziphansi.

2. Umshini wokumaka we-laser ungenza ukuqoshwa kwensimbi okungashoni, futhi usebenzisa i-laser enamandla amakhulu ukwenza amamaki angapheli ezindaweni ezihlukahlukene zensimbi nezingezona ezensimbi.Umthelela wokumaka uyamelana nokugqwala futhi uvimbela ukuphazamisa okunonya.

3. Ukusebenza kahle okuphezulu kokucubungula, ukulawulwa kwekhompiyutha, kulula ukukubona okuzenzakalelayo.

4. Umshini wokumaka we-laser unezinzuzo zokungathintani, akukho mandla okusika, ithonya elincane elishisayo, futhi ngeke kulimaze indawo noma ingaphakathi lento ephrintiwe, ukuqinisekisa ukunemba kwangempela kwe-workpiece.

5. Ijubane lokumaka liyashesha, i-laser beam elawulwa yikhompyutha ingahamba ngesivinini esikhulu (5-7 m / s), inqubo yokumaka ingaqedwa ngemizuzwana embalwa, umphumela ucacile, isikhathi eside futhi muhle. .

6. Izinketho ezihlukahlukene, ezinemodi yokukhetha ukusebenza kwesofthiwe yekhodi enezinhlangothi ezimbili, ingakwazi ukubona ukulungiswa kokugxilwa kokumaka okumile noma ukumaka okundizayo emugqeni wokukhiqiza.

Umdwebo oyisethenjwa wosayizi wepayipi, usayizi kanye nomphumela wokumaka.

Impendulo yekhasimende

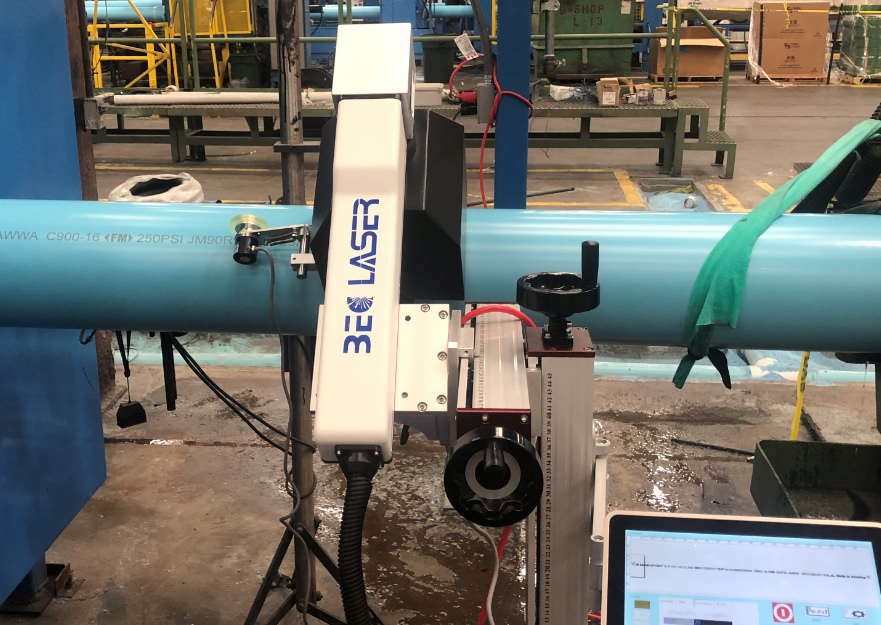

Isithombe esingezansi sivela empendulweni yangempela evela kukhasimende u-JM Eagle.