I-Laser Engraving & Cutting for Jewelry

Abantu abaningi bakhetha ukwenza ubucwebe babo bube ngeyakho ngokuqoshwa nge-laser.Lokhu kunikeza abasiki bengqephu nezitolo ezingongoti kwezobucwebe isizathu sokuthi batshale imali kulobu buchwepheshe besimanje.Ngenxa yalokho, ukuqoshwa kwe-laser kungena ngokuphawulekayo embonini yobucwebe, ngekhono layo lokuqopha cishe noma yiluphi uhlobo lwensimbi kanye nezinketho engazinikeza.Izindandatho zomshado nezomshado, isibonelo, zingenziwa zikhetheke nakakhulu ngokwengeza umlayezo, idethi noma isithombe esinengqondo kumthengi.

Ukuqoshwa nge-laser nokumaka nge-laser kungasetshenziswa ukubhala imilayezo yomuntu siqu nezinsuku ezikhethekile kubucwebe obenziwe cishe nganoma iyiphi insimbi.Nakuba ubucwebe bendabuko benziwa kusetshenziswa igolide, isiliva neplatinamu, abaklami bobucwebe besimanje basebenzisa ezinye izinsimbi ezifana ne-tungsten, insimbi ne-titanium ukuze bakhe izingcezu zemfashini.Ngohlelo lokumaka nge-laser olukhiqizwe i-BEC LASER, ungakwazi ukwengeza imiklamo eyingqayizivele kunoma iyiphi into yobucwebe yekhasimende lakho, noma ukwengeza inombolo ye-serial noma olunye uphawu lokuhlonza ukuze umnikazi akwazi ukuqinisekisa into ngezinjongo zokuphepha.Ungakwazi futhi ukwengeza isifungo ngaphakathi kwendandatho yomshado.

Umshini wokuqopha nge-laser uyinto okufanele ube nawo wonke umkhiqizi nomthengisi ebhizinisini lobucwebe.Ukuqopha izinsimbi, ubucwebe, nezinye izinto kube umkhuba ovame kakhulu kusukela kudala.Kodwa muva nje kuye kwasungulwa imishini yokuqopha nge-laser esezingeni eliphezulu ngendlela emangalisayo engaxazulula zonke izinkinga zakho zokumaka ezinsimbi nezingezona ezensimbi.

Kungani i-Laser Engraving?

I-Laser engraving iyindlela yesimanje yokudala imiklamo.Noma ngabe kungukudala umbhalo wegolide wesitayela sakudala, ukuqopha izindandatho, ukwengeza umbhalo okhethekile ewashini, ukuhlobisa umgexo noma ukwenza isongo ngezifiso ngokusiqopha, i-laser ikunikeza ithuba lokusebenza kumajamo nezinto zokwakha ezingenakubalwa.Izimpawu ezisebenzayo, amaphethini, ukwakheka, ukwenza kube ngokwakho ngisho nokuqoshwa kwezithombe kungafinyelelwa kusetshenziswa umshini we-laser.Kuyithuluzi lokudala lemboni yokudala.

Ngakho-ke yini ekhetheke kangaka ngokuqoshwa kwe-laser, futhi yini umehluko phakathi kwale ndlela nokuqoshwa kwendabuko?Kancane, empeleni:

√ I-laser ihlinzeka ngobuchwepheshe obuhlanzekile, obuvumelana nemvelo, obungenamakhemikhali nezinsalela futhi obungahlangani nobucwebe.

√ Ubuchwepheshe be-laser bunikeza umenzi wezinto eziyigugu ithuba lokudala imiklamo emihle ngaphandle kobungozi entweni ngokwayo.

√ Imiphumela yokuqoshwa kwe-laser ngemininingwane enembile, ehlala isikhathi eside kunomdwebo wendabuko.

√ Kuyenzeka uqophe umbhalo noma ihluzo endabeni ekujuleni okuqondile.

√ Ukudweba nge-laser kusebenza kangcono ezinsimbini eziqinile, ngokuvamile kuphila isikhathi eside.

I-BEC Laser ihlinzeka ngemishini yokuqopha ngobucwebe be-laser yesimanje enembile futhi enembile enokuqina okuphezulu.Ihlinzeka ngophawu lwelaser olungathinteki, olumelana nemihuzuko, oluhlala njalo cishe kunoma yiluphi uhlobo lwempahla ehlanganisa igolide, iplatinamu, isiliva, ithusi, insimbi engagqwali, i-carbide, ithusi, i-titanium, i-aluminium kanye nezinhlobonhlobo zama-alloys namapulasitiki.

Umbhalo wokuhlonza, izinombolo ze-serial, amalogo ezinkampani, i-matrix yedatha engu-2-D, ibhakhodi, izithombe eziyingcaca nezedijithali, nanoma iyiphi idatha yenqubo ngayinye ingakhiqizwa ngokuqoshwa kwe-laser.

Amasistimu okuqoshwa kwe-laser anamandla aphezulu ayakwazi nokusika izinsimbi ezincane zokudala i-monogram kanye nemigexo yamagama kanye nokunye ukusikwa kwedizayini eyinkimbinkimbi.

Kusukela ezitolo zobucwebe bezitini nodaka kuya ekuthengeni ku-inthanethi, abathengisi banikeza imigexo yokusika amagama ukuze ithengiswe.Le migexo yamagama kulula ukuyenza usebenzisa amasistimu wokumaka we-laser athuthukile kanye nesoftware yokumaka nge-laser.Izinketho ezitholakalayo zihlanganisa: amagama okuqala, ama-monograms, amagama okuqala neziteketiso ngesitayela noma ifonti oyikhethile.

Laser Cutting Machine for Jewelry

Abaklami bobucwebe nabakhiqizi baqhubeka befuna izixazululo ezinokwethenjelwa zokukhiqiza ukusika okunembayo kwezinsimbi eziyigugu.Ukusika i-fiber laser enamazinga aphezulu wamandla, ukugcinwa okuthuthukisiwe nokusebenza okungcono kuvela njengokukhetha okuphezulu kwezicelo zokusika ubucwebe, ikakhulukazi izinhlelo zokusebenza lapho ikhwalithi ephezulu yomkhawulo, ukubekezelelana okuqinile nokukhiqizwa okuphezulu kuyadingeka.

Amasistimu wokusika we-laser angasika izinhlobonhlobo zezinto zokuqina okuhlukahlukene futhi afaneleka kahle ekudaleni izimo eziyinkimbinkimbi.Ngaphezu kwalokho, ama-laser e-fiber andisa ukunemba, ukuguquguquka okusikiwe kanye nokuphuma futhi anikeze isixazululo sokusika esisebenzayo esibizayo esinembayo ngenkathi ngesikhathi esifanayo enikeza abaklami bobucwebe inkululeko yokwenza izimo eziyinselele ezingavinjelwa izindlela zokusika zendabuko.

Ukusika i-Laser kuyindlela ekhethwayo yokwenza amagama anqunywe kanye nemigexo ye-monogram.Enye yezinhlelo zokusebenza zobucwebe ezisetshenziswa kakhulu zamalaser, ukusika kusebenza ngokuqondisa ugongolo lwelaser olunamandla aphezulu eshidini lensimbi elikhethelwe igama.Ilandelela uhlaka lwegama kufonti ekhethiwe ngaphakathi kwesofthiwe yokuklama, futhi okokusebenza okuveziwe kuyancibilika noma kushiswe.Amasistimu okusika nge-laser anembe kuze kube phakathi kwama-micrometer ayi-10, okusho ukuthi igama lishiywe nomkhawulo wekhwalithi ephezulu kanye nokuqedwa okubushelelezi, okulungele ukuthi ubucwebe bengeze izihibe zokunamathisela iketango.

Igama elilengayo elisikiwe lifika ngezinhlobonhlobo zezinsimbi.Ukuthi ikhasimende likhetha igolide, isiliva, ithusi, ithusi, insimbi engagqwali noma i-tungsten, ukusika nge-laser kuhlala kuyindlela enembe kakhulu yokwakha igama.Izinhlobonhlobo zezinketho zisho ukuthi lena ithrendi engagcini kwabesifazane kuphela;amadoda ngokuvamile akhetha izinsimbi ezisindayo kanye nefonti egqamile, futhi abucwebe ngokuvamile bazama ukuhlanganisa zonke izintandokazi.Insimbi engagqwali, ngokwesibonelo, ithandwa ngamadoda ngoba inomuzwa okhululekile ngayo, futhi ukusika nge-laser kusebenza kangcono ensimbi kunanoma iyiphi enye indlela yokwenziwa.

Ukuqeda kubaluleke kakhulu ekusikeni kwamagama ekhwalithi, imiklamo kanye nama-monograms, futhi lesi ngesinye isizathu esenza ukusika i-laser kube ukukhetha kokuqala kobucwebe abaningi bokukhiqiza.Ukuntuleka kwamakhemikhali anokhahlo kusho ukuthi isisekelo sensimbi asilinyazwa yinqubo, futhi unqenqema olucacile lushiya igama elisikwe ngobushelelezi elilungele ukupholishwa.Inqubo yokupholisha incike ensimbi ekhethiwe nokuthi ikhasimende lifuna ukucwebezela okuphezulu noma ukuqedwa kwe-matte.

Ngezansi kunezinzuzo ezimbalwa zemishini yokusika i-laser uma kuqhathaniswa nezindlela zokusika zendabuko:

√ Ukuhlanekezela okuncane ezingxenyeni ngenxa yendawo encane ethintekile ukushisa

√ Ukusika ingxenye eyinkimbinkimbi

√ Ububanzi be-kerf obuncane

√ Ukuphindaphinda okuphezulu kakhulu

Ngesistimu yokusika i-laser ungakha kalula amaphethini wokusika ayinkimbinkimbi wemiklamo yakho yobucwebe:

√ Interlocking Monograms

√ Ama-Monograms Endilinga

√ Yisho Imigexo

√ Imiklamo Yangokwezifiso Eyinkimbinkimbi

√ Izihlokwana nezintelezi

√ Amaphethini Ayinkimbinkimbi

Uma ufuna umshini wokusika ubucwebe be-laser osebenza kahle kakhulu, lapha batusa umshini wokusika ubucwebe be-BEC we-laser.

Jewelry Laser Welding

Phakathi neminyaka embalwa edlule, intengo yemishini eminingi yobucwebe yokushisela i-laser yehlile, okuyenza ifinyeleleke kakhulu kubakhiqizi bobucwebe, izitudiyo zokuklama ezincane, izitolo zokulungisa nobucwebe bezitolo kuyilapho inikeza izici ezengeziwe kanye nokuvumelana nezimo kumsebenzisi.Imvamisa, labo abathenge umshini wokushisela we-laser wobucwebe bathola ukuthi isikhathi, umsebenzi nokonga kwezinto ezibonakalayo kubonakale kuyidlula kakhulu inani lokuthenga lokuqala.

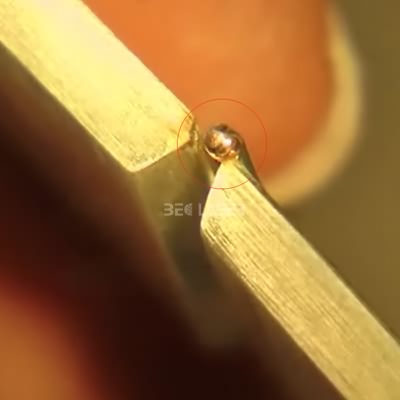

I-laser welding yobucwebe ingase isetshenziselwe ukugcwalisa i-porosity, i-re-tip platinum noma izilungiselelo ze-prong zegolide, ukulungisa izilungiselelo ze-bezel, ukulungisa/ukushintsha usayizi wamasongo namasongo ngaphandle kokukhipha amatshe nokulungisa amaphutha okukhiqiza.Ukushisela nge-laser kulungisa kabusha ukwakheka kwamangqamuzana okufana nezinsimbi ezifanayo noma ezingafani endaweni yokushisela, okuvumela ama-alloys amabili avamile ukuba abe munye.

Ubucwebe bokukhiqiza nokudayisa okwamanje abasebenzisa ama-laser welders bavame ukumangala ngezinhlelo eziningi ezahlukene kanye nekhono lokukhiqiza umkhiqizo wekhwalithi ephezulu ngesikhathi esincane ngezinto ezimbalwa ngenkathi ususa imiphumela yokushisa ngokweqile.

Enye yezinto ezibalulekile ekwenzeni i-laser welding isebenze ekukhiqizeni nasekulungiseni ubucwebe kwaba ukuthuthukiswa komqondo "ohamba mahhala".Ngale ndlela, i-laser ikhiqiza ukukhanya kwe-infrared okumile okuqondiswe ngoboya obuphambanayo be-microscope.I-laser pulse ingalawulwa ngosayizi nokuqina.Ngenxa yokuthi ukushisa okukhiqiziwe kuhlala kusendaweni, ama-opharetha angakwazi ukuphatha noma ukulungisa izinto ngeminwe, ukushisela izindawo ezincane nge-pin-point ngaphandle kokudala umonakalo eminwe noma ezandleni zomqhubi.Lo mqondo ohamba mahhala wenza abasebenzisi bakwazi ukuqeda amadivaysi okulungisa abizayo futhi bakhulise uhla lokuhlanganisa ubucwebe nokulungisa izinhlelo zokusebenza.

Ukushisela amabala asheshayo konga abasebenzi basebhentshini ukuphuthaza okuningi.Ama-lasers welders aphinde avumele abaklami ukuthi basebenze kalula ngezinsimbi ezinzima njengeplatinamu nesiliva, futhi bagweme ukushisisa ngephutha nokuguqula amatshe ayigugu.Umphumela uba umsebenzi osheshayo, ohlanzekile owenza umugqa ophansi.

Iningi labacwebi banethemba elithile lokuthi i-laser welder ingasiza kanjani noma ingasiza ebhizinisini labo lobucwebe.Ngemuva kwesikhashana nelaser, izinkampani eziningi zithi i-laser yenza okungaphezu kwalokho ebezicabanga ukuthi izokwenza.Ngomshini ofanele kanye nokuqeqeshwa okufanele, abenzi bobucwebe abaningi bazobona ushintsho olukhulu ngesikhathi nemali esetshenziswe kule nqubo entsha.

Ngezansi uhlu olufushane lwezinzuzo ze-laser welding:

√ Uqeda isidingo solder materials

√ Akusekho ukukhathazeka mayelana ne-karat noma ukufanisa umbala

√ I-Firescale kanye ne-picling iyaqedwa

√ Nikeza ukunemba okuqondile kwamajoyinti ashiselwe ngelaser ahlanzekile, ahlanzekile

√ I-Laser weld spot ububanzi isukela ku-0,05mm - 2,00mm

√ Ukwakheka Kwe-Pulse Kokukhipha Okulungile

√ Ukushisa kwendawo kuvumela "ukudonsa okuningi" ngaphandle kokulimaza umsebenzi wangaphambilini

√ Small, mobile, enamandla futhi kulula ukusebenza

√ Isistimu yokupholisa amanzi ehlangene, eziqukathise

Izicelo zobucwebe be-laser welding:

√ Lungisa izinhlobo eziningi zobucwebe namafreyimu wezibuko ngemizuzu

√ Shisela noma yimuphi usayizi wocezu lobucwebe kusukela ekubunjweni okukhulu kuya ezintanjeni ezincane zefiligree

√ Shintsha usayizi wamasongo futhi ulungise izilungiselelo zamatshe

√ Hlanganisa ngokuphelele amasongo ethenisi edayimane

√ Izigxobo zokushisela i-laser kumacici angemuva

√ Lungisa izingcezu zobucwebe ezilimele ngaphandle kokukhipha amatshe

√ Lungisa/Gcwalisa kabusha izimbobo ze-porosity ekubunjweni

√ Lungisa/Phinda uhlanganise amafreyimu engilazi yamehlo

√ Kuhle kakhulu ezinhlelweni zokushisela i-Titanium