I-laser welding iyindlela yokushisela esetshenziselwa ukuhlanganisa izingcezu eziningi zensimbi kusetshenziswa i-laser beam.Uhlelo lwe-laser welding luhlinzeka ngomthombo wokushisa ogxilile, ovumela ukushisela okuncane, okujulile kanye namazinga aphezulu okushisela.Le nqubo isetshenziswa kaningi ezinhlelweni zokushisela zevolumu ephezulu, njengasembonini yezimoto.

I-laser welding isheshisa inqubo yokushintsha izingxenye ezifojiwe ngezingxenye ezinesitembu.I-laser welding isetshenziselwa ukufaka esikhundleni sokushisela kwamabala ahlukene ngokushisela kwe-laser okuqhubekayo, okunganciphisa ububanzi bokugqagqana nezinye izingxenye eziqinisayo, futhi kungacindezela ivolumu yesakhiwo somzimba ngokwaso.Ngenxa yalokho, isisindo somzimba wemoto singancishiswa ngo-56kg.Ukusetshenziswa kwe-laser welding kufinyelele ekunciphiseni isisindo kanye nokunciphisa ukungcola, okuhlangabezana nezidingo zokuvikelwa kwemvelo enkathini yanamuhla.

I-laser welding isetshenziswa ekuthungeni amapuleti okujiya angalingani, futhi izinzuzo zibaluleke kakhulu.Lobu buchwepheshe buguqula inqubo yokukhiqiza yendabuko-okokuqala ukunyathela kube izingxenye, bese kuba khona ukushisela kube into ephelele: okokuqala ngokushisela izingxenye ezimbalwa ezinobukhulu obuhlukahlukene zibe zizonke, bese ugxiviza futhi ukwakheka, ukunciphisa inani lezingxenye nokusebenzisa izinto zokwakha ezengeziwe.Kunengqondo, ukwakheka kanye nomsebenzi kuthuthukiswa kakhulu.

Izindlela zokushisela i-laser zivame ukusetshenziselwa ukushisela izingxenye ezihlukene zomzimba.Okulandelayo uhlu lwezindlela ezimbalwa zokushisela i-laser ezivame ukusetshenziswa embonini yezimoto.

(1) I-laser brazing

I-Laser brazing isetshenziswa kakhulu ekuxhumekeni kwekhava ephezulu kanye nodonga oluhlangothini, isivalo se-trunk, njll. I-Volkswagen, i-Audi, i-Peugeot, i-Ford, i-Fiat, i-Cadillac, njll bonke basebenzisa le ndlela yokushisela.

(2) Ukushisela i-laser self-fusion

I-laser self-fusion welding ingeye-deep penetration welding, esetshenziselwa ikakhulukazi uphahla kanye namapaneli aseceleni, iminyango yemoto, njll. Njengamanje, izimoto eziningi zohlobo lweVolkswagen, Ford, GM, Volvo nabanye abakhiqizi basebenzisa i-laser self-fusion welding.

(3) Ukushisela okukude kwe-laser

Ukushisela okukude nge-laser kusebenzisa irobhothi + galvanometer, ukuma kwe-remote beam + ukushisela, futhi inzuzo yakho isekufinyezeni kakhulu isikhathi sokuma nokusebenza kahle okuphezulu uma kuqhathaniswa nokucutshungulwa kwe-laser evamile.

I-laser welding ingasetshenziswa futhi ku-cigar lighter, okokuphakamisa ama-valve, ama-cylinder gaskets, ama-injection kaphethiloli, ama-spark plugs, amagiya, ama-side shafts, ama-drive shafts, ama-radiator, ama-clutch, amapayipi e-injini akhipha amandla, ama-axle e-supercharger, kanye nokulungiswa kwe-airbag liner kanye ne-splicing yemoto eyonakele. izingxenye.

Ukushisela nge-laser kunezinzuzo nezinzuzo eziningi kunezindlela zokushisela zendabuko futhi kunganciphisa kakhulu izindleko ngenkathi kuthuthukisa ukusebenza kahle kokukhiqiza kanye nekhwalithi.

I-laser welding inezici ezilandelayo:

①Ibanga lokushisa elincane (ligxilile).

②Indawo yesenzo nendawo zilawuleka ngokunembile.

③Indawo ethinteke ukushisa incane.

④I-deformation yokushisela incane, futhi akukho ukulungiswa kwe-post-welding okudingekayo.

⑤ Ukucutshungulwa okungeyena othintana naye, asikho isidingo sokucindezela i-workpiece kanye nokwelashwa kwendawo.

⑥Ingabona ukushiselwa kwezinto ezingafani.

⑦ Ijubane lokushisela liyashesha.

⑧Alikho ithonya elishisayo, akukho msindo futhi akukho ukungcola emhlabeni ongaphandle.

Imishini enconyiwe elungele i-welding auto imi kanje:

Laser Welding Machine for Mold

Ngokuthuthuka kwemboni, ubuchwepheshe be-laser welding bucwaningwa njalo futhi buqanjwe kabusha.Njengamanje, embonini ye-welding yemishini, umshini wokushisela we-laser odumile ngenxa yezici zawo ezivelele zokusebenza futhi ubonisa izici ezinhle zenqubo ngesikhathi senqubo yokushisela.Ngakho ingasetshenziswa kabanzi emikhakheni eminingi.

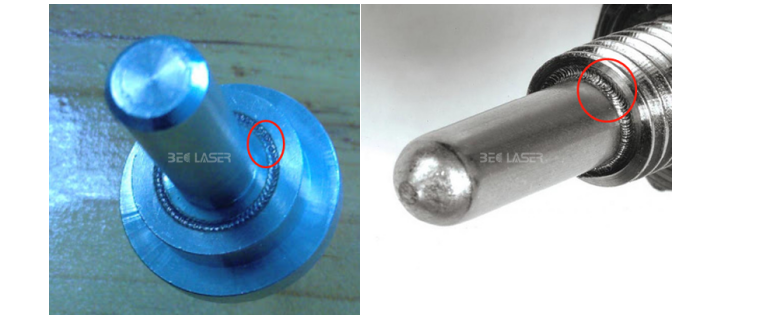

Isikhunta ku-mold laser welding sidlala indima ebaluleke kakhulu embonini yesimanje, futhi ikhwalithi yayo inquma ngokuqondile ikhwalithi yomkhiqizo.Ukuthuthukisa impilo yesevisi kanye nokunemba kwesikhunta kanye nokunciphisa umjikelezo wokukhiqiza isikhunta yizinkinga zobuchwepheshe izinkampani eziningi ezidinga ukuzixazulula ngokushesha.Kodwa-ke, izindlela zokuhluleka ezifana nokuwa, ukuguqulwa, ukuguga, ngisho nokuphuka ngokuvamile kwenzeka ngesikhathi sokusebenzisa isikhunta.Ngakho-ke, ubuchwepheshe bokukhanda i-laser welding nabo buyadingeka ekulungiseni isikhunta.

Umshini wokushisela we-laser wuhlobo olusha lwendlela yokushisela, ikakhulukazi yokushisela izinto ezinodonga oluncane kanye nezingxenye eziqondile.Iyakwazi ukubona ukushisela izinqe, ukushisela izinqe, ukushisela imithungo, ukushisela uphawu, njll., ene-aspect ratio ephezulu, ububanzi obuncane bokushisela, kanye nendawo ethinteke ukushisa.I-deformation encane, encane, isivinini sokushisela, i-welding seam ebushelelezi futhi enhle, asikho isidingo noma ukucutshungulwa okulula ngemva kokushisela, izinga eliphezulu le-welding seam, azikho izimbobo zomoya, ukulawula okunembile, indawo encane yokugxila, ukunemba kokuma okuphezulu, nokulula ukukubona okuzenzakalelayo.

Isibonelo esijwayelekile sokusetshenziswa kwe-laser welding embonini yesikhunta umshini wokukhanda isikhunta we-laser welding.Le mishini kulula ukuyisebenzisa opharetha, ingakhuphula kakhulu isivinini sokulungiswa kwe-welding, futhi umphumela wokulungisa nokunemba kuseduze nokuhle, okwenza imishini Isetshenziswe kabanzi emkhakheni we-mold welding.Indawo ethintekile yokushisa kwe-welding yalo mshini wokushisela incane kakhulu, futhi ayidingi ukushiswa kusengaphambili, futhi i-workpiece e-welded ayibonakali i-annealing phenomenon ngemva komsebenzi.Lobu buchwepheshe bokukhanda i-laser abukwazi ukusetshenziselwa ukulungisa ukugqokwa kwesikhunta kuphela, kodwa futhi bungafinyelela ukushisela okunembile kwezingxenye zomzimba ezahlukahlukene.

Isikhathi sokuthumela: Jul-15-2021