Eminyakeni yamuva, ukuthuthukiswa kwemboni yokukhiqiza kuye kwashesha kakhulu, futhi isidingo sokucutshungulwa kwensimbi sikhuphuke.I-Welding ingenye yezinqubo ezibalulekile zokucubungula insimbi, futhi izindlela zokushisela zendabuko azikwazanga ukuhlangabezana nezidingo zokukhiqiza.Ngaphansi kwalesi sisekelo, i-umshini wokushisela we-laser ophethwe ngesandlayazalwa, eyadunyiswa kabanzi lapho yethulwa, futhi yashintsha ngokushesha indawo yemakethe yokushisela ipuleti elincanyana.

Iumshini wokushisela we-laser ophethwe ngesandlaiyisizukulwane esisha semishini yokushisela i-laser.Okokushisela okungeyena othintana naye.Ayidingi ingcindezi ngesikhathi sokusebenza., encibilikisa i-material ngaphakathi, bese ipholisa futhi icwebezelise ukwenza i-weld.

a.Awekho amandla angaphandle azosetshenziswa endaweni yokusebenza

Lapho umshini wokushisela we-laser ophethwe ngesandla ucubungula izingxenye, njengoba ungeke uhlangane nezingxenye ezicutshunguliwe, ngeke kube nokucindezeleka kwangaphandle ezingxenyeni ezicutshunguliwe phakathi nayo yonke inqubo yokushisela, futhi ukuhlushwa kwamandla okukhiqizwa yi-laser kukhulu kakhulu. phezulu.Ithonya elishisayo endaweni ezungezile yengxenye lincane kakhulu, ngakho-ke ingxenye ngeke ikhubazekile ngesikhathi sokushisela.

b.Ukushisela phakathi kwezinto ezingafani kungenziwa

Enqubweni yendabuko yokushisela, imvamisa ama-workpieces amabili kuphela enziwe ngento efanayo angashiselwa, kodwa inqubo yokushisela i-laser yomshini wokushisela we-laser ophethwe ngesandla awukwazi ukushisela indawo ephezulu yokuncibilika nezinto ezihlukahlukene okunzima ukuzincibilikisa nokushisela. , Njenge-titanium alloy, i-aluminium alloy nezinye izinto.Ngaphezu kwalokho, ubuchwepheshe be-laser welding processing bungakwazi futhi ukubona ukushisela phakathi kwezinye izinto ezingafani, zephule umkhawulo wokushisela phakathi kwezinto.

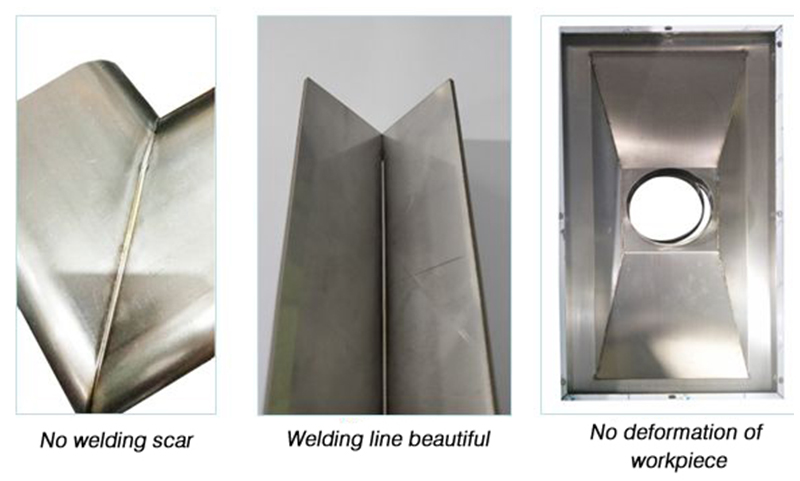

c.Umthungo we-welding emincane, ukubukeka okuhle nokuhle

Ubuchwepheshe bokushisela i-laser bomshini wokushisela we-laser obanjwe ngesandla buthuthuke kakhulu, akugcini nje ngokungcolisa imvelo, kodwa futhi kwakha amalunga amancane e-solder, imithungo emincane yokushisela, isakhiwo somphetho we-welding welding, ama-pores ambalwa kakhulu kanye nokukhubazeka, okunganciphisa futhi nokwandisa ukungcola impahla umzali, Ngakho-ke, ngemva Welding, hhayi nje ukumelana ezihlukahlukene zinhle kakhulu, kodwa ingaphezulu impahla futhi Lihle kakhulu futhi muhle.

Izici zeumshini wokushisela we-laser ophethwe ngesandla:

1. Idivayisi incane ngosayizi

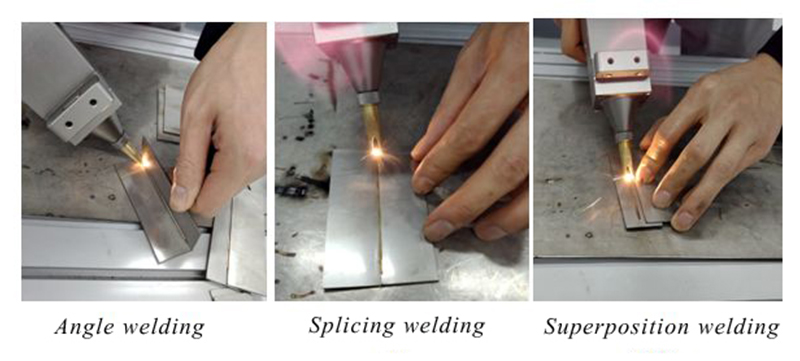

2. Ukusebenza okuguquguqukayo nokulula, kungabona ukushisela ngaphandle

3. Ikhwalithi enhle ye-beam, isivinini esisheshayo, ukuguqulwa okuncane kokushisa, ukunemba nokuhlanganiswa okuphezulu

4. Umthungo we-welding muhle, uyisicaba futhi awunazo izimbotshana, futhi akukho ukwelashwa noma ukwelashwa okulula okudingekayo ngemuva kokushisela.

5. Isibhamu sokushisela esiphethwe ngesandla singashisela i-workpiece kunoma iyiphi i-engeli, efanelekile endaweni yokushisela ama-welds ayinkimbinkimbi namadivayisi ahlukahlukene.

Izinzuzo zomshini wokushisela we-laser ophethwe ngesandla:

1. Ukusebenza kulula futhi kulula ukuyisebenzisa: umshini we-laser welding ophethwe ngesandla kulula ukuwusebenzisa futhi unezindleko eziphansi zabasebenzi.

2. Isivinini sokushisela esisheshayo: Umshini wokushisela we-laser ophethwe ngesandla uyi-welding eqhubekayo, amandla e-beam aminyene, i-welding iyasebenza futhi inesivinini esikhulu, indawo yokushisela incane, indawo ethintekile ekushiseni incane, umthungo wokushisela ubushelelezi. futhi enhle, futhi inqubo yokugaya elandelayo iyancipha.

3. Izinto ezihlukahlukene zokushisela: Umshini wokushisela we-laser ophethwe ngesandla ungashisela izinto zensimbi ezivamile ezifana namapuleti ensimbi engagqwali, amapuleti ensimbi, amapuleti anamaka, namapuleti e-aluminium.

4. Izidingo eziphansi zokucubungula imvelo: Umshini we-laser welding ophethwe ngesandla awudingi itafula elikhethekile lokushisela, imishini ithatha indawo encane, futhi ukucubungula kuyavumelana nezimo.Ifakwe ngamamitha amaningana emigqa yokunwetshwa kwefiber optical, engahanjiswa ukuze kusetshenziswe ibanga elide ngaphandle kwemikhawulo yendawo yemvelo.

5. Umsebenzi oqhubekayo: I-laser ifakwe imishini yokupholisa amanzi, engaqinisekisa umsebenzi oqhubekayo wokuqina okuphezulu.

6. Ukusebenza kwezindleko eziphezulu: Umshini we-laser welding ophethwe ngesandla awukwazi ukwenza imisebenzi yokushisela kuphela, kodwa futhi ulungise isikhunta.Impilo yelaser ingamahora ayi-100,000, okuyinde kakhulu kunempilo yesevisi yemishini ejwayelekile, futhi iyonga.

Ukuqhathaniswa kokusetshenziswa kwamandla phakathiumshini wokushisela we-laser ophethwe ngesandlakanye ne-argon arc welding:

Uma kuqhathaniswa nokushisela kwe-arc evamile, umshini wokushisela we-laser ophethwe ngesandla wonga cishe u-80% kuya ku-90% wamandla kagesi, futhi izindleko zokucubungula zingancishiswa cishe ngo-30%.Ukuqhathanisa umphumela wokushisela: umshini wokushisela we-laser ophethwe ngesandla ungaqedela insimbi engafani kanye nokushisela kwensimbi okungafani.Isivinini esisheshayo, ukuwohloka okuncane kanye nendawo ethintekile yokushisa.Ama-welds mahle, ayisicaba, futhi awanawo/amancane ama-porosity.I-laser ebanjwa ngesandla yezingxenye ezincane ezivulekile kanye nokushisela.Ukuqhathanisa okulandelayo kwenqubo: Umshini wokushisela we-laser obanjwe ngesandla unokufaka okuphansi kokushisa kanye nokuguqulwa okuncane kwendawo yokusebenza ngesikhathi sokushisela, futhi ungathola indawo enhle yokushisela ngaphandle noma kuphela ukwelashwa okulula (kuye ngokuthi izidingo ze-welding surface effect).Umshini wokushisela we-laser ophethwe ngesandla unganciphisa kakhulu izindleko zabasebenzi zenqubo enkulu yokupholisha nokubeka izinga.

Izinkambu zokufaka isicelo zomshini wokushisela we-laser ophethwe ngesandla:

Ikakhulukazi indawo emisiwe yeshidi lensimbi elikhulu neliphakathi nendawo, ikhabethe, i-chassis, umnyango we-aluminium alloy kanye nohlaka lwewindi, isitsha sokugeza insimbi engagqwali nezinye izinto zokusebenza ezinkulu njenge-engeli engaphakathi kwesokudla, i-engeli yangaphandle kwesokudla, ukushisela indiza, ukushisa okuncane kuthintekile. indawo ngesikhathi sokushisela, i-deformation encane, kanye nokujula kwe-welding Enkulu futhi eshiselwe ngokuqinile.Isetshenziswa kakhulu ekhishini nasembonini yokugezela, imboni yemishini yasendlini, imboni yokukhangisa, imboni yesikhunta, imboni yomkhiqizo wensimbi engagqwali, imboni yobunjiniyela bensimbi engagqwali, imboni yomnyango newindi, imboni yezandla, imboni yemikhiqizo yasendlini, imboni yefenisha, imboni yezingxenye zezimoto, njll.

Isicelo kanye nobuhlakani beimishini yokushisela lasersebeyimishini enamandla kumishini yezimboni.Ukusebenza okuphezulu kokucubungula kanye nezici ezinhle kakhulu zokucubungula zemishini yokushisela i-laser ebanjwe ngesandla kudale iminikelo ephezulu ekukhiqizeni amabhizinisi amakhulu., futhi kuwukukhetha kwezitshalo ezengeziwe zokucubungula.

Isikhathi sokuthumela: May-10-2023