Ububanzi bokusetshenziswa kweimishini yokushisela laserliya ngokuya liba banzi, kodwa izidingo nazo ziya ngokuya zikhula.Ngesikhathi senqubo yokushisela, igesi yokuvikela idinga ukushaywa ukuze kuqinisekiswe ukuthi umphumela wokushisela womkhiqizo muhle.Ngakho-ke ungasebenzisa kanjani ukushaywa komoya ngendlela efanele kwinqubo ye-metal laser welding?

Ku-laser welding, igesi yokuvikela ithinta ukwakheka kwe-weld, ikhwalithi ye-weld, ukungena kwe-weld nobubanzi, njll. Ezimweni eziningi, igesi evikelayo evuthelayo izoba nomthelela onenzuzo ku-weld, kodwa ingaba nomthelela omubi uma isetshenziswe ngokungalungile.

Umthelela omuhle wokuvikela igesiumshini wokushisela we-laser:

1. Ukuvunguza kahle igesi evikelayo kungavikela ngempumelelo i-weld pool ukuze kuncishiswe i-oxidation, noma ngisho nokugwema ukufakwa i-oxidized.

2. Inganciphisa ngokuphumelelayo i-spatter ekhiqizwa inqubo yokushisela, futhi idlale indima yokuvikela isibuko esigxile noma isibuko sokuzivikela.

3. Ingakwazi ukukhuthaza ukusabalalisa iyunifomu ye-weld pool lapho iqina, ukuze i-weld ifane futhi ibe yinhle.

4. Inganciphisa ngempumelelo ama-weld pores.

Uma nje uhlobo lwegesi, izinga lokugeleza kwegesi kanye nendlela yokuphefumula kukhethwa ngendlela efanele, umphumela omuhle ungatholakala.Kodwa-ke, ukusetshenziswa okungafanele kwegesi yokuvikela kungaba nemiphumela emibi ekushiseleni.

Imiphumela emibi yokusetshenziswa okungalungile kwegesi yokuvikela ekushiseni kwe-laser:

1. Ukungeniswa okungafanele kwegesi evikelayo kungase kubangele ukushisela okungalungile.

2. Ukukhetha uhlobo olungalungile lwegesi kungase kubangele imifantu endaweni yokushisela futhi kungase kubangele nokuncipha kwezakhiwo zemishini ye-weld.

3. Ukukhetha izinga lokugeleza lokuphephuka kwegesi okungalungile kungase kuholele ku-oxidation eyingozi kakhulu ye-weld (ukuthi izinga lokugeleza likhulu kakhulu noma lincane kakhulu), noma kungase kubangele ukuthi insimbi ye-weld pool iphazamiseke kakhulu ngamandla angaphandle, okubangela ukushisela ukuwa noma ukwakha ngokungalingani.

4. Ukukhetha indlela engalungile yokuphefumula kwegesi kuzobangela ukuthi i-weld ihluleke ukufeza noma ingabi namphumela wokuvikela noma ibe nomthelela omubi ekubunjweni kwe-weld.

Uhlobo lwegesi yokuvikela:

Okuvame ukusetshenziswalaser weldingamagesi okuvikela ikakhulukazi i-N2, i-Ar, He, futhi izakhiwo zawo ezingokomzimba namakhemikhali zihlukile, ngakho-ke umphumela we-weld nawo uhlukile.

I-Argon

Amandla we-ionization we-Ar aphansi ngokuqhathaniswa, futhi izinga le-ionization ngaphansi kwesenzo se-laser liphakeme ngokuqhathaniswa, elingahambisani nokulawula ukwakheka kwamafu e-plasma, futhi kuzoba nomthelela othile ekusetshenzisweni ngempumelelo kwe-laser.Kodwa-ke, umsebenzi we-Ar uphansi kakhulu, futhi kunzima ukusabela ngamakhemikhali ngezinsimbi ezivamile.ukusabela, futhi izindleko ze-Ar aziphezulu.Ngaphezu kwalokho, ukuminyana kwe-Ar kukhulu, okuvumela ukucwila phezulu kwe-weld pool, engavikela kangcono i-weld pool, ngakho-ke ingasetshenziswa njengegesi evamile yokuvikela.

I-nitrogen N2

Amandla e-ionization we-N2 aphakathi, aphakeme kunalawo e-Ar, futhi aphansi kunalawo ka-He.Ngaphansi kwesenzo se-laser, i-ionization degree iphakathi, enganciphisa kangcono ukwakheka kwefu le-plasma, ngaleyo ndlela kwandise ukusetshenziswa okusebenzayo kwe-laser.I-nitrogen ingasabela ngamakhemikhali nge-aluminium alloy ne-carbon steel ekushiseni okuthile ukuze ikhiqize ama-nitride, okuzokwandisa ukuqina kwe-weld futhi kunciphise ukuqina, okuzoba nomthelela omubi kakhulu kuzakhiwo zemishini ye-weld joint, ngakho-ke akunconywa ukusebenzisa i-nitrogen.I-aluminium alloy kanye ne-carbon steel welds ivikelekile.I-nitride ekhiqizwa ukusabela kwamakhemikhali phakathi kwe-nitrogen nensimbi engagqwali ingathuthukisa amandla e-weld joint, ezosiza ukuthuthukisa izakhiwo zemishini ye-weld, ngakho-ke i-nitrogen ingasetshenziswa njengegesi yokuvikela lapho i-welding insimbi engagqwali.

Helium Yena

Unamandla aphezulu kakhulu e-ionization, futhi i-ionization degree iphansi kakhulu ngaphansi kwesenzo se-laser, esingalawula kahle ukwakheka kwefu le-plasma.Kuyigesi enhle yokuvikela i-weld, kepha izindleko zikaYe ziphakeme kakhulu.Ngokuvamile, le gesi ayisetshenziswa emikhiqizweni ekhiqizwa ngobuningi.Ngokuvamile usetshenziselwa ucwaningo lwesayensi noma imikhiqizo enenani eliphakeme kakhulu elingeziwe.

Njengamanje kunezindlela ezimbili zokuvunguza ezijwayelekile zokuvikela igesi: ukuvuthela kwe-side-shaft kanye nokuvunguza nge-coaxial.

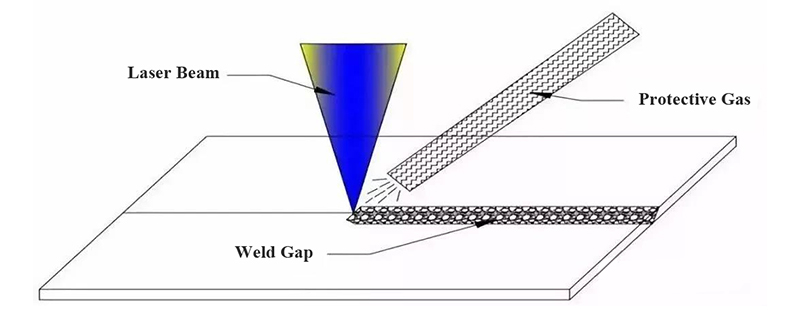

Umfanekiso 1: Ukuvuthela kwe-Side-shaft

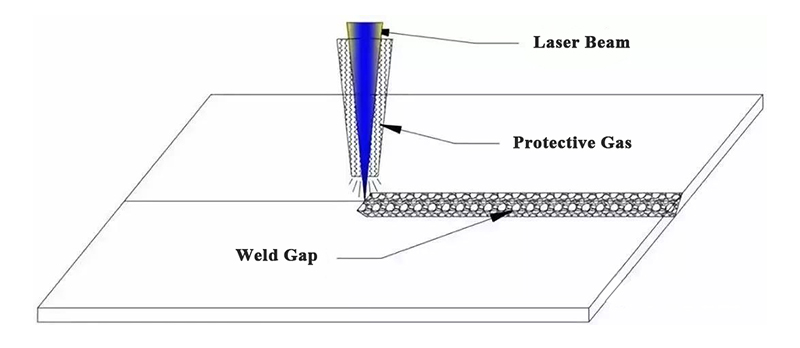

Umfanekiso 2: I-Coaxial Blowing

Indlela yokukhetha izindlela ezimbili zokuphefumula kuwukucatshangelwa okuphelele.Ngokuvamile, kunconywa ukusebenzisa indlela yegesi yokuvikela evuthela ohlangothini.

Umgomo wokukhetha wendlela yokuvikela ukuvunguza kwegesi: kungcono ukusebenzisa i-paraxial kumashisela omugqa oqondile, kanye ne-coaxial yezithombe ezivaliwe zendiza.

Okokuqala, kufanele kucace ukuthi lokho okubizwa ngokuthi "i-oxidation" ye-weld yigama elivamile kuphela.Ngokombono, kusho ukuthi i-weld isabela ngamakhemikhali ngezingxenye eziyingozi emoyeni, okuholela ekuwohlokeni kwekhwalithi ye-weld.Kuvamile ukuthi insimbi yokushisela isezingeni lokushisa elithile.Isabela ngamakhemikhali anomoya-mpilo, i-nitrogen, i-hydrogen, njll. emoyeni.

Ukuvimbela i-weld ekubeni "i-oxidized" ukunciphisa noma ukuvimbela izingxenye ezinjalo eziyingozi ukuthi zingathintani nensimbi yokushisela emazingeni okushisa aphezulu, hhayi nje insimbi encibilikisiwe yechibi, kodwa kusukela ngesikhathi insimbi yokushisela incibilika kuze kube yilapho i-pool metal iqina. futhi izinga lokushisa layo lehla ngaphansi kwezinga elithile lokushisa phakathi nenkathi.

Ngokwesibonelo, ukushisela i-titanium alloy kungamunca ngokushesha i-hydrogen lapho izinga lokushisa lingaphezu kuka-300 °C, umoya-mpilo ungamuncwa ngokushesha lapho izinga lokushisa lingaphezu kuka-450 °C, futhi i-nitrogen ingamuncwa ngokushesha lapho ingaphezu kuka-600 °C, ngakho i-titanium i-alloy weld iqinisiwe futhi izinga lokushisa lincishiswa libe ngu-300 ° C Izigaba ezilandelayo zidinga ukuvikelwa ngokuphumelelayo, ngaphandle kwalokho zizobe "i-oxidized".

Akunzima ukuqonda kusukela encazelweni engenhla ukuthi igesi yokuvikela eshaywayo ayidingi nje kuphela ukuvikela i-weld pool ngesikhathi esifanele, kodwa futhi idinga ukuvikela indawo esanda kuqina eshiselwe, ngakho-ke ngokuvamile uhlangothi lwe-shaft side. kusetshenziswe kuMfanekiso 1.Vuthela igesi evikelayo, ngoba uhla lokuvikela lwale ndlela lubanzi kunalolo lwendlela yokuvikela i-coaxial ku-Figure 2, ikakhulukazi indawo lapho i-weld isanda kuqina inokuvikela okungcono.

Kuzinhlelo zokusebenza zobunjiniyela, akuyona yonke imikhiqizo engasebenzisa igesi evikela uhlangothi lwe-shaft side.Kweminye imikhiqizo ethile, igesi yokuvikela i-coaxial kuphela ingasetshenziswa, okudingeka yenziwe kusuka esakhiweni somkhiqizo kanye nefomu elihlangene.Ukukhetha okuhlosiwe.

Ukukhetha izindlela eziqondile zokuphephetha igesi yokuvikela:

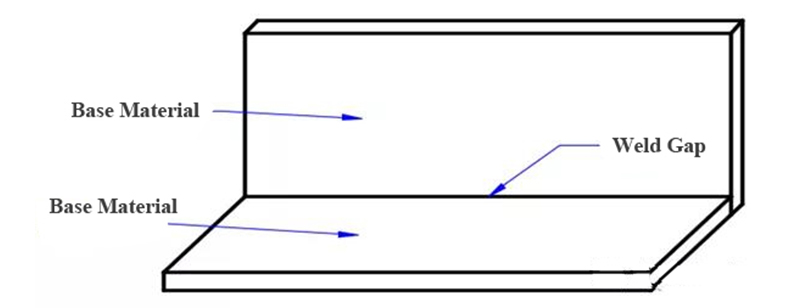

1. Ama-Welds aqondile

Njengoba kuboniswe kuMdwebo 3, ukuma komthungo wokushisela womkhiqizo kuwumugqa oqondile, futhi ifomu elihlangene liyilunga le-butt, i-lap joint, i-lap joint seam ekhoneni langaphakathi noma i-lap welded joint.Kungcono ukushaya igesi yokuvikela ohlangothini lwe-shaft.

Umfanekiso 3: Ama-Welds aqondile

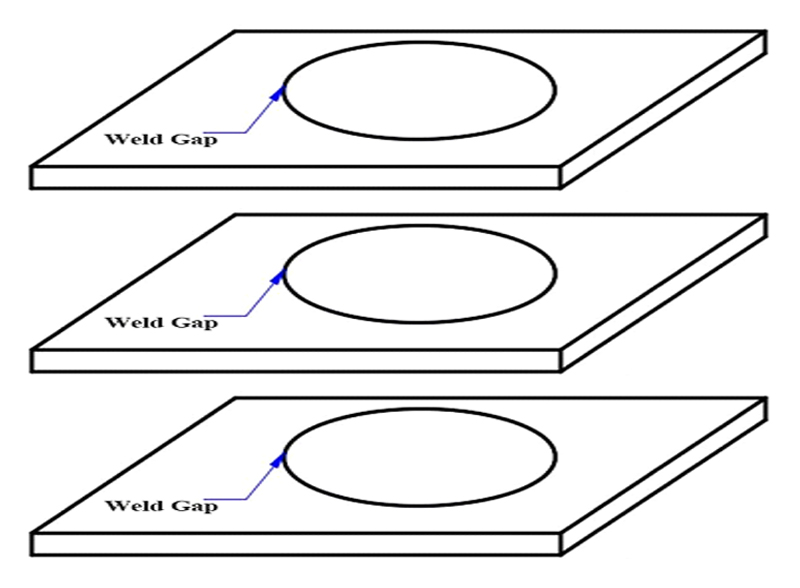

2. Amashisela wesithombe avaliwe

Njengoba kuboniswe kuMfanekiso 4, ukuma komthungo we-welding womkhiqizo kuyisimo esivaliwe njengesiyingi sendiza, i-polygon yendiza, kanye nomugqa we-multi-segment wendiza.Kungcono ukusebenzisa indlela yegesi yokuvikela i-coaxial eboniswe kuMfanekiso 2.

Umfanekiso 4: Ama-Welds Wezithombe Avaliwe

Ukukhethwa kwegesi yokuvikela kuthinta ngqo ikhwalithi, ukusebenza kahle kanye nezindleko zokukhiqizwa kwe-welding.Kodwa-ke, ngenxa yokwehlukahlukana kwezinto zokushisela, ukukhethwa kwegesi yokushisela nakho kuyinkimbinkimbi enqubweni ye-welding yangempela.Kuyadingeka ukuthi ucabangele ngokuphelele izinto zokushisela, izindlela zokushisela, kanye nezikhundla zokushisela.Kanye nomphumela wokushisela odingekayo, kuphela ngokuhlolwa kokushisela kungakhethwa igesi yokushisela efanelekile ukuze kuzuzwe imiphumela engcono yokushisela.

Isikhathi sokuthumela: May-08-2023