Okwamanje,imishini yokushisela laserzisetshenziswe kabanzi ekuhlobiseni ukukhangisa, ubucwebe, iminyango namafasitela nezinye izimboni.Uyini umehluko phakathi kwe-laser welding kanye ne-argon arc welding, i-soldering nobunye ubuchwepheshe bendabuko bokushisela?Yini eyenza iumshini wokushisela we-laserukuthembela ekutheni kancane kancane ube yinkambiso yobuchwepheshe bamanje bokushisela?

Umshini wokushisela we-laseriwuhlobo olusha lwendlela yokushisela, ikakhulukazi yokushisela izinto ezinodonga oluncane kanye nezingxenye ezinhle, ezingaqedela ukushisela indawo, ukushisela izinqe, ukuthunga ukushisela, ukufaka uphawu, njll. Usayizi omncane, ukuguqulwa okuncane, isivinini sokushisela okusheshayo, isicaba kanye umthungo omuhle we-welding, asikho isidingo noma ukwelashwa okulula kuphela ngemuva kokushisela, ikhwalithi ephezulu ye-welding seam, akukho pores, ukulawulwa okunembile, indawo encane yokukhanya, ukunemba kokuma okuphezulu, kulula ukuqedela okuzenzakalelayo.Isebenzisa i-laser enamandla amakhulu ukushisisa ingxenye yezinto endaweni encane.Amandla emisebe ye-laser ahlakazeka ezintweni ngokusebenzisa ukushisa kokushisa, ancibilikise i-material ukuze akhe ichibi elithile elincibilikisiwe, abese encibilikisa izinto ezimbili ezixhumene ndawonye.

Isebenza kanjani i-laser welding

I-laser welding iwukuba i-irradiate ugongolo lwe-laser olunamandla aphezulu endaweni yensimbi, futhi ngokusebenzisa ukuxhumana phakathi kwe-laser nensimbi, insimbi iyancibilika ukuze yakhe i-weld.Ukuncibilika kwensimbi kungenye yezinto ezibonakalayo ngesikhathi sokusebenzisana kwe-laser nensimbi.Ngezinye izikhathi amandla okukhanya awaguqulwa kakhulu abe ukuncibilika kwensimbi, kodwa abonakaliswa kwezinye izinhlobo, njengokuhwamuka, ukwakheka kwe-plasma, njll. Nokho, ukuze kuzuzwe ukushiselwa okuhle kwe-fusion, ukuncibilika kwensimbi kufanele kube yindlela evelele yokuguqulwa kwamandla.Kulokhu, kuyadingeka ukuqonda izenzakalo ezihlukahlukene zomzimba ezikhiqizwa ekusebenzisaneni phakathi kwe-laser nensimbi kanye nobudlelwano phakathi kwalezi zenzakalo ezibonakalayo namapharamitha we-laser, ukuze iningi lamandla e-laser likwazi ukulawulwa ngokulawula imingcele ye-laser.

Iguqulwa ibe amandla okuncibilika kwensimbi ukuze kufezwe injongo yokushisela.

Imingcele yenqubo ye-laser welding

1.Ukuminyana kwamandla

Ukuminyana kwamandla kungenye yemingcele ebaluleke kakhulu ekucutshungulweni kwe-laser.Ngokuminyana kwamandla okuphezulu, isendlalelo esingaphezulu singashiswa sifike endaweni yokubilisa ebangeni lesikhathi le-microsecond, okuholela enanini elikhulu lokuhwamuka.Ngakho-ke, ukuminyana kwamandla aphezulu kunenzuzo ezinqubweni zokususa izinto ezifana nokubhoboza, ukusika, nokuqopha.Ukuze uthole ukuminyana kwamandla aphansi, kuthatha ama-millisecond ambalwa ukuze izinga lokushisa elingaphezulu lifike endaweni yokubilisa.Ngaphambi kokuba ingaphezulu lihwamuke, ungqimba olungezansi lufinyelela endaweni encibilikayo, okulula ukwenza i-fusion weld enhle.Ngakho-ke, ekushiseni kwe-laser conduction, ukuminyana kwamandla kububanzi obungu-104~106W/cm2.

2.Laser pulse waveform

I-Laser pulse shape iyinkinga ebalulekile ekushiseleni nge-laser, ikakhulukazi ekushiseleleni amashidi amancane.Uma i-laser enamandla kakhulu ishaya phezu kwezinto ezibonakalayo, u-60~98% wamandla e-laser azovezwa futhi alahleke endaweni yensimbi, futhi ukubonakala kwayo kuyahlukahluka nezinga lokushisa elingaphezulu.Ngesikhathi sokusebenza kwe-laser pulse, ukubonakaliswa kwezinsimbi kuyahlukahluka kakhulu.

3.Laser ishayela ububanzi

Ububanzi be-Pulse bungenye yemingcele ebalulekile ye-pulse laser welding.Akuyona nje ipharamitha ebalulekile ehlukile ekususweni kwezinto ezibonakalayo kanye nokuncibilika kwezinto, kodwa futhi ipharamitha eyinhloko enquma izindleko nevolumu yemishini yokucubungula.

4. Umthelela wenani le-defocus kwikhwalithi yokushisela

Ukushisela nge-laser ngokuvamile kudinga indlela ethile yokususa ukugxilisa ingqondo, ngoba ukuminyana kwamandla phakathi nendawo lapho kugxilwe khona nge-laser kuphezulu kakhulu, futhi kulula ukuhwamuka kungene embobeni.Ukusatshalaliswa kokuminyana kwamandla kuyafana ngokuqhathaniswa kuzo zonke izindiza kude nalapho kugxilwe khona i-laser.

Kunezindlela ezimbili zokususa ukugxila: ukugxilisa okuhle nokubi.Indiza egxile ngaphezu kocwecwe lokusebenza i-positive defocus, ngaphandle kwalokho i-negative defocus.Ngokombono we-geometrical optics, lapho i-defocus ilungile, ukuminyana kwamandla endizeni ehambisanayo kucishe kufane, kodwa ukwakheka kwechibi elincibilikisiwe elitholiwe empeleni kuhlukile.Uma i-defocus ingalungile, ukujula okukhulu kokungena kungatholakala, okuhlobene nenqubo yokwakheka kwechibi elincibilikisiwe.Ukuhlola kubonisa ukuthi lapho i-laser ishiselwa ku-50 ~ 200us, impahla iqala ukuncibilika, yenze insimbi yesigaba soketshezi futhi ihwamuke, yakhe isitimu sokucindezela kwemakethe, esikhishwa ngesivinini esikhulu kakhulu, sikhipha ukukhanya okumhlophe okukhazimulayo.Ngesikhathi esifanayo, ukugcwala okuphezulu komhwamuko kuhambisa insimbi ewuketshezi iye onqenqemeni lwechibi elincibilikisiwe, yenze ukucindezeleka phakathi nendawo yechibi elincibilikisiwe.Uma i-defocus inegethivu, ukuminyana kwamandla wangaphakathi wezinto ezibonakalayo kuphezulu kunalowo ongaphezulu, futhi kulula ukwenza ukuncibilika okunamandla nokuhwamuka, ukuze amandla okukhanya adluliselwe ekujuleni kwento.Ngakho-ke, ekusetshenzisweni okusebenzayo, lapho ukujula kokungena kuyadingeka ukuba kube kukhulu, kusetshenziswa ukugxilwa okungalungile;lapho welding izinto ezincane, defocusing positive kufanele kusetshenziswe.

Uma kuqhathaniswa nobuchwepheshe bokushisela bendabuko,umshini wokushisela we-laserinezinzuzo ezilandelayo

1. Inemisebenzi ehlukahlukene ephelele, futhi i-welding seam incane, engakwazi ukubona ukushisela okunembayo;

2. Isakhiwo sesakhiwo sisebenziseka kalula, ikhanda le-laser linganwetshwa emuva naphambili, kwesokunxele nakwesokudla, phezulu naphansi ngesandla, lilungele ukushisela okungaxhunywanga nokude kwemikhiqizo ehlukahlukene;

3. I-welding seam ibushelelezi, isakhiwo se-welding sifana, azikho izimbotshana, akukho ukungcola, kanye namaphutha ambalwa okufakwa;

4. Ijubane lokushisela liyashesha, isilinganiso se-aspect sikhulu, ukuguqulwa kuncane, futhi ukusebenza kuzinzile, okungakwazi ukubona ukukhiqizwa kwenqwaba okuzenzakalelayo;

4.Kuwuhlobo olusha lwendlela yokushisela.I-laser welding ihloselwe ikakhulukazi ukushisela izinto ezinodonga oluncane kanye nezingxenye ezinembile.Ingakwazi ukubona ukushisela kwe-spot, i-butt welding, i-stitch welding, i-sealing welding, njll. Indawo encane ethintekile, ukuguqulwa okuncane, isivinini sokushisela okusheshayo, i-welding seam ebushelelezi futhi enhle, asikho isidingo noma ukwelashwa okulula ngemva kokushisela, izinga eliphezulu le-welding seam, akukho pores, ukulawula okunembile, indawo encane yokugxila, ukunemba kokuma okuphezulu, ukufinyeleleka kalula kwe-Automation, ngakho-ke kuthandwa kakhulu ngabasebenzisi, akuthuthukisi nje ukusebenza kahle kokukhiqiza nokucubungula, kodwa futhi kunciphisa umsebenzi onzima olandelayo wangemva kokucubungula.

Imboni yokushisela i-laser

Imboni yezimoto, imboni yesikhunta, imboni yezokwelapha, imboni yobucwebe, njll. Izimboni ezahlukene zidinga imishini yokushisela i-laser ehlukene.

Uhlobo lweumshini wokushisela we-laser

1.Fiber laser welding machine-Handheld Type

2.Isikhunta laser welding machine- Uhlobo Lwemanuwali

3.Cantilever laser welding machine-Ngengalo evilaphayo

4.3-I-axis laser welding machine-Uhlobo oluzenzakalelayo

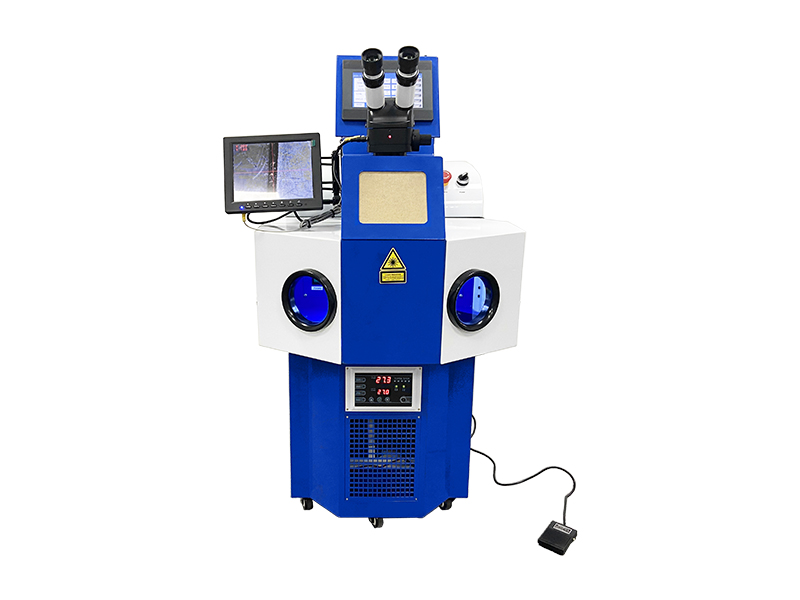

5.Jewelry laser welding machine-Desktop Uhlobo

6.Umshini wokushisela we-laser wobucwebe–I-Inbuilt Water Chiller

7.Jewelry laser welding machine-Hlukanisa Amanzi Chiller

Amasampula:

Isikhathi sokuthumela: Apr-27-2023