Umshini wokumaka we-laserukusetshenziswa kwemishayo ye-laser ukumaka unomphela ubuso bezinto ezahlukahlukene.Umthelela wokumaka uwukuveza izinto ezijulile ngokuhwamuka kwezinto ezingaphezulu, noma “uqopha” imikhondo ngokusebenzisa amakhemikhali nokomzimba wento engaphezulu ebangelwa amandla okukhanya, noma ukushisa ingxenye yento ngokusebenzisa amandla okukhanya. , ekhombisa ukuqoshwa okudingekayo.iphethini, umbhalo

Izicelo:

Ingakwazi ukuqopha izinto ezihlukahlukene ezingezona ezensimbi.Isetshenziswa kwezesekeli zokugqoka, ukupakishwa kwemithi, ukupakishwa kwewayini, izitsha zobumba, ukupakisha isiphuzo, ukusika indwangu, imikhiqizo yenjoloba, ama-nameplates egobolondo, izipho zobungcweti, izinto zikagesi, isikhumba nezinye izimboni.

1. Ingakwazi ukuqopha insimbi nezinto ezihlukahlukene ezingezona ezensimbi.Ifaneleka kakhulu ukucutshungulwa kweminye imikhiqizo edinga ukunemba okuhle nokuphezulu.

2. Isetshenziswa ezingxenyeni zikagesi, amasekethe ahlanganisiwe (IC), izinto zikagesi, ukuxhumana kweselula, imikhiqizo yehadiwe, izesekeli zamathuluzi, izinsimbi ezinembile, izibuko namawashi, ubucwebe, izingxenye zezimoto, izinkinobho zepulasitiki, izinto zokwakha, amapayipi e-PVC, okokwelashwa nokunye. izimboni .

3. Izinto ezisetshenziswayo zihlanganisa: izinsimbi ezivamile nama-alloys (zonke izinsimbi ezifana nensimbi, ithusi, i-aluminium, i-magnesium, i-zinc, njll.), izinsimbi ezingavamile kanye nama-alloys (igolide, isiliva, i-titanium), ama-oxide ensimbi (zonke izinhlobo zama-oxide ensimbi okwamukelekayo), Ukwelashwa okukhethekile kwendawo (i-phosphating, i-aluminium anodizing, indawo ye-electroplating), impahla ye-ABS (igobolondo likagesi likagesi, izidingo zansuku zonke), uyinki (okhiye abashintshashintshayo, imikhiqizo ephrintiwe), i-epoxy resin (i-electronic component packaging, insulating layer).

Jewelry Laser Ukumaka Machine:

Izindlela zokumaka nezindlela zokuqopha zomshini wokumaka we-laser jewelry fiber ziguquguquka kakhulu.Udinga nje ukufaka umbhalo oshiwo noma iphethini kusofthiwe.Imishini yokumaka nge-laser ingamaka futhi iqophe izinhlamvu ezifunwayo ngemizuzwana, inikeze ubucwebe ubuhle obuyingqayizivele bokuqoshwa ngokwezifiso.Ukumakwa kwe-laser kusebenzisa inqubo yokumaka engathinteki, esebenzisa i-laser enamandla amakhulu ukuminyanisa ingxenye engaphezulu yento ukuze kuhwamuke into engaphezulu noma kukhiqizwe ukusabela kwamakhemikhali kokushintsha kombala, ngaleyo ndlela kushiye amamaki ahlala njalo.Yonke inqubo yokuqopha ayinakho ukuthintana okuqondile nobucwebe, akukho ukungqubuzana komshini, futhi akukho monakalo ebuhlotsheni.Ngaphezu kwalokho, indawo ye-laser incane, ukushaqeka okushisayo nakho kuncane, futhi izinhlamvu ezimakiwe zinhle kakhulu futhi azikho monakalo kubucwebe.

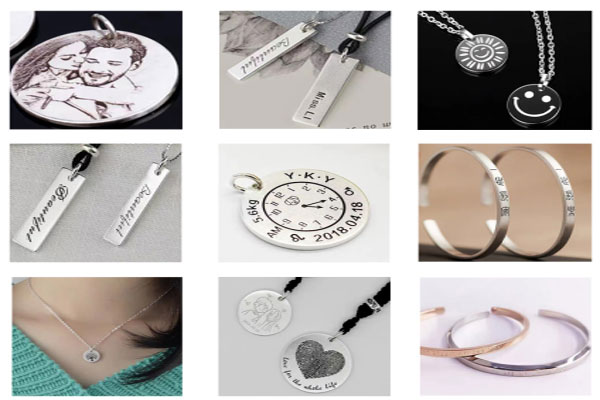

Imishini yokumaka i-laser yobucwebe njengamanje isetshenziswa kabanzi kumacici, imigexo, izindandatho, namasongo neminye imikhiqizo.Ukuncintisana embonini yobucwebe kuya ngokuya kushuba.Imikhiqizo esitolo sobucwebe emakethe icishe ifane.Amasu okucubungula angaphambilini afana nokugxiviza kwensimbi, ubuchwepheshe bokuqopha nokuqoshwa, indlela yokuncibilika, ubuchwepheshe bokufakwa kwensimbi emnyama nesiliva, kanye nensimbi yokusanhlamvu yokhuni kudla isikhathi futhi kubiza.Umshini wokumaka we-jewelry fibre laser womaka unezici zokunemba okuphezulu, ofaneleka kakhulu ekuqoshweni izinhlamvu ezingagqoki nezihlala isikhathi eside ebusweni bobucwebe obuyigugu nobuncane njengamandandatho nemigexo.

Inzuzo:

Izici zokunemba okuphezulu zeimishini yokumaka laserzilungele ukuqedela izimpawu ezihlala njalo ezingagqoki kubucwebe obuyigugu nobuncane njengamandandatho namakholomu.Ezinxanxatheleni zezitolo zanamuhla zobucwebe, izimpawu zomuntu siqu zithandwa kakhulu phakathi kwamakhasimende, njengamagama, izibusiso nezithombe eziqondene nawe ezinezincazelo ezikhethekile ezimakwe kubucwebe.Ngaphezu kwalokho, umshini wokumaka we-laser ungaphinda ugcwalise izimpawu ezahlukahlukene ebusweni bezinto eziningi ezifana nethusi, insimbi engagqwali, isiliva negolide.

1. Ikhwalithi ye-beam yinhle, futhi ingaqopha ngokunembile ama-workpieces amancane kakhulu, ama-slits ayisicaba futhi amahle, futhi isivinini sokuqopha siyashesha, okulethela amakhasimende isipiliyoni esisebenzayo nesiyongayo sokucubungula;

2. Izinga eliphezulu lokuguqulwa kwe-electro-optical, akukho ukulahlekelwa kokuhlanganisa amandla, akukho okusebenzisekayo, ukonga izindleko zokusebenza kumakhasimende.

3. I-fiber laser inempilo ende yesevisi, amandla okukhipha i-laser azinzile, ukwethembeka okuphezulu, nokungakhathalelwa amahora angu-100,000;

4. Isivinini sokumaka siyashesha, ukusebenza kahle kuphezulu, isikhathi sokucubungula i-batch se-workpieces sifushane, futhi inzuzo ngesikhathi seyunithi kanye nomkhiqizo owodwa ukhuliswa;

I-5.Indiza ekhethekile inekhono eliqinile lokwenza ngokwezifiso futhi ingenziwa ngokuvumelana nezidingo zamakhasimende.

Izindlela zokumaka nezindlela zokuqopha zomshini wokumaka we-laser jewelry fibre

zivumelana nezimo kakhulu.Udinga nje ukufaka umbhalo oshiwo noma iphethini kusofthiwe.Imishini yokumaka i-laseringamaka futhi iqophe izinhlamvu ezifunwayo ngemizuzwana, inikeze ubucwebe ubuhle obuyingqayizivele bokuqoshwa ngokwezifiso.Ukumakwa kwe-laser kusebenzisa inqubo yokumaka engathinteki, esebenzisa i-laser enamandla amakhulu ukuminyanisa ingxenye engaphezulu yento ukuze kuhwamuke into engaphezulu noma kukhiqizwe ukusabela kwamakhemikhali kokushintsha kombala, ngaleyo ndlela kushiye amamaki ahlala njalo.Yonke inqubo yokuqopha ayinakho ukuthintana okuqondile nobucwebe, akukho ukungqubuzana komshini, futhi akukho monakalo ebuhlotsheni.Ngaphezu kwalokho, indawo ye-laser incane, ukushaqeka okushisayo nakho kuncane, futhi izinhlamvu ezimakiwe zinhle kakhulu futhi azikho monakalo kubucwebe.

Isikhathi sokuthumela: Jun-29-2023