Umshini wokushisela we-laseriwuhlobo lwemishini yokushisela evame ukusetshenziswa ekukhiqizeni izimboni, futhi ingumshini obalulekile wokucubungula impahla ye-laser.Imishini yokushisela i-laser iye yavuthwa kancane kancane kusukela ekuthuthukisweni kokuqala kuze kube manje, futhi izinhlobo eziningi zemishini yokushisela ziye zatholakala.

I-laser welding iwuhlobo olusha lwendlela yokushisela kanye nesinye sezici ezibalulekile zokusetshenziswa kobuchwepheshe bokucubungula impahla.I-laser welding ihloselwe ikakhulukazi ukushisela izinto ezinodonga oluncane kanye nezingxenye ezinembile.Inqubo yokushisela ingeyohlobo lwe-heat conduction, okungukuthi, ingaphezulu le-workpiece lishisiswe ngemisebe ye-laser, futhi ukushisa okungaphezulu kudlula. ukulawula amapharamitha afana nobubanzi, amandla, amandla aphezulu kanye nemvamisa yokuphindaphinda kwe-laser pulse.Iyakwazi ukubona ukushisela, i-butt welding, i-stitch welding, i-sealing welding, njll. Ububanzi be-welding seam buncane, indawo ethintekile ukushisa incane, ukuguqulwa kuncane, isivinini sokushisela siyashesha, umthungo wokushisela uyashelela futhi muhle, futhi akukho ukwelashwa noma ukwelashwa okulula okudingekayo ngemva kokushisela.I-welding seam ingeyekhwalithi ephezulu, ayinazo izimbotshana, ingalawulwa ngokunembile, inendawo encane yokugxila, futhi inokunemba kokuma okuphezulu, futhi kulula ukuzenzela.

Ukulungiswa komshini wokushisela we-laser:

Iumshini wokushisela we-laseridinga ukulungiswa, futhi izinga lokushisa lethangi lamanzi lidinga ukulungiswa ebusika nasehlobo.Vimbela izinga lokushisa legumbi ukuthi lingabandi kakhulu noma lishise kakhulu ukuze lithinte amandla okukhipha i-laser.Kunconywa ukuthi ulungise izinga lokushisa lethangi lamanzi libe ngama-3 ~ 5 degrees ngaphansi kwezinga lokushisa legumbi ngokusho kwegumbi lokushisa, elingakwazi kuphela ukuqinisekisa amandla okukhipha i-laser, kodwa futhi liqinisekise ukuzinza kokukhishwa kwe-laser.

1. Ukusetha izinga lokushisa kwamanzi

Ukushisa kwamanzi okupholisa kunomthelela oqondile ekusebenzeni kahle kokuguqulwa kwe-electro-optical, ukuzinza kanye ne-condensation.Ngaphansi kwezimo ezijwayelekile, izinga lokushisa lamanzi okupholisa lihlelwe kanje: amanzi ahlanzekile (abizwa nangokuthi amanzi aphansi, asetshenziselwa ukupholisa imojula yomshini wokushisela we-laser), izinga lokushisa lamanzi lesekethe yamanzi kufanele libekwe cishe ku-21 °C, futhi ingasethwa ngokufanelekile phakathi kuka-20 no-25 °C ngokwesimo.Ukulungisa.Lokhu kulungiswa kudinga ukwenziwa uchwepheshe.

Izinga lokushisa lamanzi lamanzi e-DI deionized (owaziwa nangokuthi amanzi okushisa okuphezulu, asetshenziselwa ukupholisa izingxenye zamehlo) kufanele abekwe phakathi kuka-27°C no-33°C.Lokhu kushisa kufanele kulungiswe ngokuvumelana nezinga lokushisa elizungezile kanye nomswakama.Uma umswakama uphezulu, izinga lokushisa lamanzi lamanzi e-DI kufanele likhuphuke ngokufanele.Isimiso esiyisisekelo sithi: Izinga lokushisa lamanzi e-DI kufanele libe ngaphezu kwendawo yamazolo.

2. Izinyathelo zokuvimbela ezifana nezingxenye zangaphakathi ze-elekthronikhi noma ze-optical

Inhloso eyinhloko ukuvimbela ukufiphala kwezingxenye ze-elekthronikhi noma ezibonakalayo ngaphakathiumshini wokushisela we-laser.Qinisekisa ukuthi i-chassis ayinawo umoya: noma ngabe iminyango yekhabhinethi ikhona futhi ivalwe ngokuqinile;kungakhathaliseki ukuthi amabhawodi okuphakamisa phezulu aqinisiwe;ukuthi ngabe isembozo esivikelayo sesixhumi esibonakalayo sokulawula ukuxhumana esingasetshenzisiwe ngemuva kwe-chassis simboziwe, nokuthi ezisetshenzisiwe zilungisiwe yini.Gcina umshini wokushisela we-laser uvuliwe futhi unake ukulandelana kokuvula nokuvala.Faka igumbi elinesiphephetha-moya lomshini wokushisela i-laser, wenze kusebenze umsebenzi wokukhipha umoya opholile futhi ugcine isiphephetha-moya sisebenza ngokuqhubekayo futhi sizinzile (kuhlanganise nasebusuku), ukuze izinga lokushisa kanye nomswakama egumbini elinesiphephetha-moya kugcinwe endaweni. 27°C no-50% ngokulandelana.

3. Hlola izingxenye zendlela yokubona

Ukuqinisekisa ukuthi i-laser ibilokhu isesimweni esijwayelekile sokusebenza, ngemuva kokusebenza okuqhubekayo noma lapho imiswa isikhathi esithile, izingxenye ezisendleleni yokubona njengenduku ye-YAG, i-diaphragm ye-dielectric kanye nengilazi yokuvikela ilensi. kufanele ihlolwe ngaphambi kokuqala ukuqinisekisa ukuthi izingxenye ze-optical azingcolile., Uma kukhona ukungcola, kufanele kusetshenzwe ngesikhathi ukuze kuqinisekiswe ukuthi ingxenye ngayinye ye-optical ngeke yonakaliswe ngaphansi kwe-laser irradiation eqinile.

4. Hlola futhi ulungise i-laser resonator

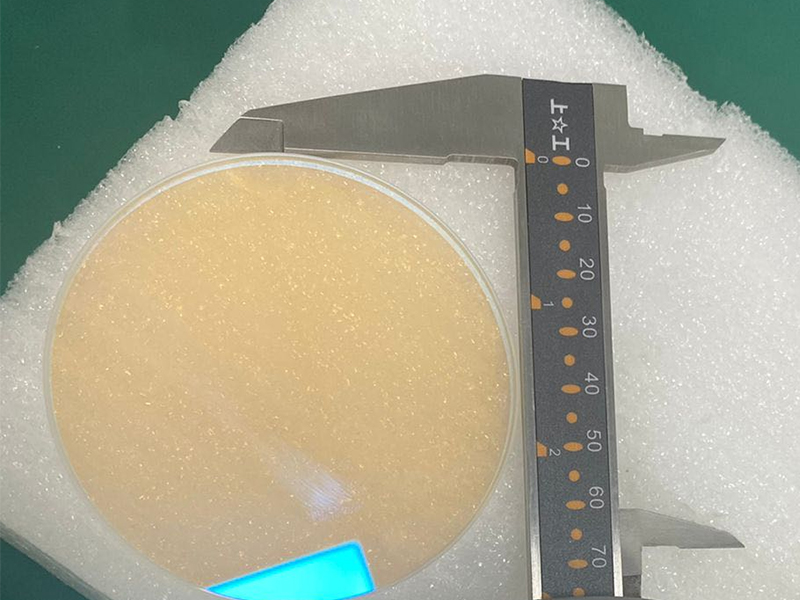

opharetha bemishini yokushisela nge-laser ngokuvamile bangasebenzisa iphepha lesithombe elimnyama ukuze bahlole indawo yokuphuma kwe-laser.Uma indawo engalingani noma ukwehla kwamandla kutholakele, i-resonator ye-laser kufanele ilungiswe kusenesikhathi ukuze kuqinisekiswe ikhwalithi ye-beam yokuphuma kwe-laser.Abaqhubi abalungisa iphutha kufanele babe nomqondo ojwayelekile wokuvikela ukuphepha kwe-laser, futhi kufanele bagqoke izibuko ezikhethekile zokuphepha nge-laser ngesikhathi somsebenzi.Ukulungiswa kwe-laser kufanele kwenziwe ngabasebenzi abaqeqeshwe ngokukhethekile, ngaphandle kwalokho ezinye izingxenye endleleni ye-optical zizolimala ngenxa yokungalungi kahle noma ukulungiswa kwe-polarization ye-laser.

5. Ukuhlanza umshini wokushisela we-laser

Ngaphambi nangemuva komsebenzi ngamunye, qala uhlanze indawo ezungezile ukuze wenze umhlabathi wome futhi uhlanzeke.Bese wenza umsebenzi omuhle wokuhlanza umshini wokushisela we-laser we-YAG, okuhlanganisa indawo engaphandle ye-chassis, uhlelo lokubuka, kanye nendawo yokusebenza, okufanele ingabi namadoti futhi ihlanzeke.Amalensi okuzivikela kufanele agcinwe ehlanzekile.

Imishini yokushisela i-laserasetshenziswa kabanzi ekucubunguleni amazinyo okufakelwa amazinyo, ubucwebe welding, Silicon steel sheet welding, inzwa welding, ikephu webhethri Welding kanye isikhunta Welding.

Isikhathi sokuthumela: May-06-2023