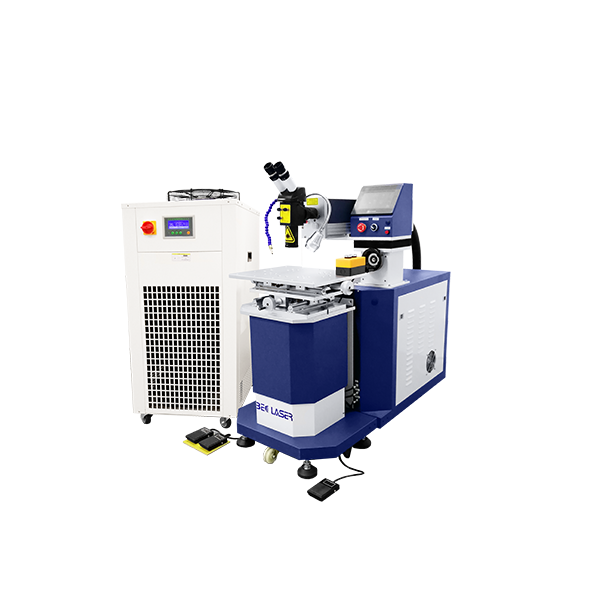

Isikhunta Laser Welding Machine-Manual Uhlobo

Isingeniso Somkhiqizo

Izitolo zanamuhla zokushisela ezisebenza ngobuchwepheshe besikhunta umjovo wepulasitiki, ukukhanda ama-dies and tooling zinezinhlobonhlobo zobuchwepheshe obusha obutholakalayo bokuthuthukisa ikhono lazo lokuhlinzeka ngezinga eliphezulu kakhulu lekhwalithi, ubuciko, kanye nesevisi kumakhasimende azo.Obunye bobuchwepheshe obukhula ngokushesha kakhulu ukusebenzisa amasistimu wokushisela we-laser njengenye indlela yokushisela ngesibonakhulu se-GTA.

Enye yezinto ezibalulekile ekwenzeni i-laser welding eyenziwa ngesandla esebenza ekukhiqizeni nasekulungiseni i-Tool and Die noma Mold kwaba ukuthuthukiswa komqondo "ohamba mahhala".Ngale ndlela, i-laser ikhiqiza ukukhanya kwe-infrared okumile okuqondiswe ngoboya obuphambanayo be-microscope.I-laser pulse ingalawulwa ngosayizi nokuqina.

I-laser welding ilungele ukuguqulwa nokulungiswa kwezibunjwa, amathuluzi futhi iyafa noma ngabe kungenxa yokulimala, ukuguga nokukhala, noma ushintsho ekwakhiweni kocezu lokusebenza.Inqubo iyashesha, inembe futhi ngeke ilimaze izindawo ezizungezile.

Idizayini esuselwe kumuntu ngokuya nge-ergonomics yenza umshini unembe, ubukeke kahle, ukusebenza okuzinzile, nempilo ende, ufaneleke kakhulu ukulungiswa kwesikhunta ngokunemba.Iwubuchwepheshe bokushisela obunembile obunamandla okushisa aphezulu e-laser, acubungula ngempumelelo ukushisela nokulungiswa kwezingxenye ezincane ezilimele zesikhunta, njenge: imifantu, amabhamuza, ukuqhekeka, ukukhanya kwesikhunta, ukuvala imiphetho, njll. isikhunta.Ithuthukiswa ngokwethulwa kobuchwepheshe obuphambili baseJalimane.

Izici

1. I-Ceramic converging cavity ayikwazi ukugqwala futhi imelana nezinga lokushisa eliphezulu, futhi ineminyaka eyi-8-10 yokuphila kwesevisi.Ukuphila kwesibani se-xenon izikhathi ezingaphezu kwezigidi ezingu-8.

2. Ukusebenzisa uhlelo oluphambili kakhulu lokuvikela ukukhanya ukuze kuqedwe ukucasuka kwamehlo ngokukhanya ngesikhathi sokusebenza.

3. Iphaneli yesikrini sokuthinta ukuze ulungise imingcele, elula futhi elula.

4. Ibhentshi lomsebenzi lingaphakanyiswa, futhi lihanjiswe ngezilinganiso ezintathu.

5. Ubukhulu bendawo yokukhanya bungashintshwa.

6. Idivayisi ejikelezayo iyakhetheka ukulungisa izinto eziyicylindrical annular.

Isicelo

Ilungele ukubunjwa komjovo ngokunemba, ukubunjwa, ukucubungula isikhunta sokushisela nezinye izimboni;zonke izinhlobo zensimbi ye-alloy ebandayo, i-alloy steel forging ephezulu, okuhlanganisa insimbi ye-nickel welding, insimbi yezinga eliphezulu, ama-alloys ethusi, i-beryllium yethusi, i-aluminium eqinile nezinye izinto zensimbi.

Amapharamitha

| Imodeli | I-BEC-MW200 | I-BEC-MW300 | I-BEC-MW400 |

| Laser Amandla | 200W | 300W | 400W |

| I-Laser Wavelength | 1064 nm | ||

| Ubukhulu.I-Single Pulse Energy | 80J | 100J | 120J |

| Uhlobo lweLaser | ND: YAG | ||

| I-Laser Pulse Frequency | 0.1-100Hz | ||

| Ububanzi be-Pulse | 0.1-20ms | ||

| Ukujula Kwe-Welding | 0.1-1.5mm | 0.1-2mm | 0.1-3mm |

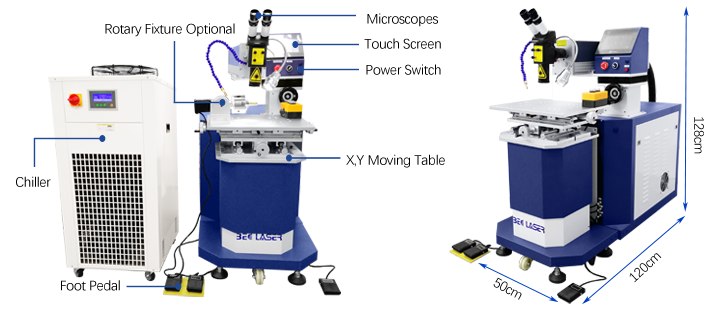

| Ibhentshi lokusebenzela | X=450mm, Y=350mm (X,Y ingalungiswa ngesandla, i-axis engu-Z ingaphakanyiswa) | ||

| Ukubuka Amasistimu | Isibonakhulu (isistimu yokuqapha yokuzikhethela ye-CCD isithombe ukuze sikhulise) | ||

| Isistimu yokulawula | Ukulawula uhlelo lwe-Microcomputer | ||

| Ukusetshenziswa kwamandla | 6KW | 10KW | 12KW |

| Uhlelo Lokupholisa | Ukupholisa amanzi | ||

| Imfuneko Yamandla | 220V±10%/380V±10% 50Hz noma 60Hz | ||

| Usayizi Wokupakisha Nesisindo | Umshini: 144 * 66 * 127cm, Chiller Amanzi: 87 * 65 * 146cm;Isisindo esiphelele singama-450KG | ||

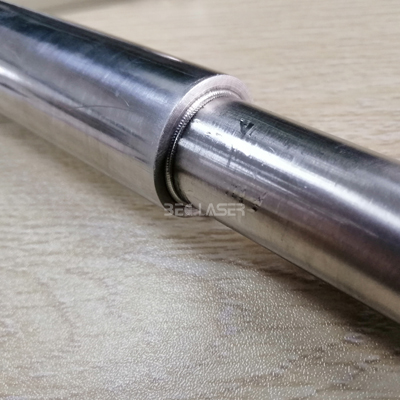

Amasampula

Izakhiwo

Imininingwane