I-Fiber Laser Welding Machine-Handheld Type

Isingeniso Somkhiqizo

Imodi yokusebenza yomshini wokushisela we-fiber laser ophethwe ngesandla, i-welding ebanjwe ngesandla iyaguquguquka futhi ilula, futhi ibanga lokushisela lide.Ukusebenzisa isibhamu sokushisela esiphethwe ngesandla esikhundleni somzila wokukhanya omisiwe wangaphambili kunezinzuzo zokusebenza okulula, ama-welding seams amahle, isivinini sokushisela okusheshayo futhi akukho okusebenzisekayo.

Ukuze Welding mncane amapuleti insimbi engagqwali, insimbi amapuleti, amapuleti lashukumisa nezinye izinto zensimbi, kungaba ngokuphelele esikhundleni bendabuko Argon arc Welding, Welding kagesi kanye nezinye izinqubo.Umshini wokushisela we-laser ophethwe ngesandla usetshenziselwa ikakhulukazi ukushisela i-laser yezindawo ezikude nezinkulu zokusebenza.Indawo ethinteke ngokushisa incane ngesikhathi sokushisela, futhi ngeke ibangele ukuguqulwa komsebenzi, i-blackening, kanye nemikhondo ngemuva.Ukujula kwe-welding kukhulu, i-welding iqinile, futhi ukuncibilika kwanele.Akukho ukubobotheka engxenyeni eyi-convex yezinto ezincibilikisiwe echibini elincibilikayo kanye ne-substrate.

Umshini we-Handheld Fiber laser welding umshini wokushisela we-laser ohlanganisa imishayo ye-laser yamandla aphezulu ku-fiber optical, ngemva kokudluliswa kwebanga elide, bese iguqulwa ibe amalambu ahambisanayo ngesibuko esihambisanayo ukuze sigxile emsebenzini ukuze kusetshenziswe ukushisela.Izindlela zokushisela zihlanganisa i-vertical welding, i-paraller welding, i-stitch welding nokunye.

Izici

1. Isivinini sokushisela esisheshayo, izikhathi ezi-2 ~ 10 ngokushesha kune-welding yendabuko.

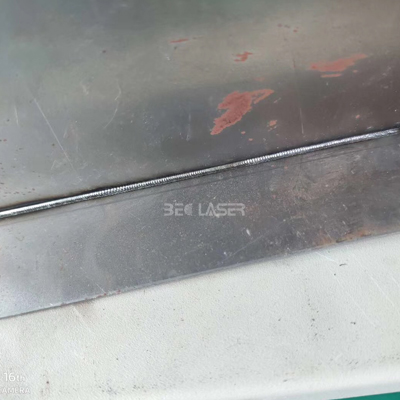

2. I-weld seam incane, ukujula kokungena kukhulu, i-taper incane, ukunemba kuphakeme, ukubukeka kushelelezi, kuyisicaba futhi kuhle.

3. Inani le-thermal deformation lincane, futhi indawo yokuncibilika kanye nendawo ethintekile ukushisa incane futhi ijulile.

4. Izinga lokupholisa eliphezulu, elingashisela isakhiwo esihle sokushisela kanye nokusebenza kahle kwamalunga.

5. I-laser welding inezinto ezincane ezisetshenziswayo nempilo ende yenkonzo.

6. Ukusebenza okulula akudingi ukuqeqeshwa, ehambisana nemvelo.

Isicelo

I-laser welding ingasetshenziswa ekushiseni insimbi engagqwali, i-aluminium, ithusi, i-chromium, i-nickel, i-titanium nezinye izinsimbi noma ama-alloys, ingasetshenziswa futhi ezinhlobonhlobo ze-welding phakathi kwezinto ezihlukahlukene, njenge: ithusi - ithusi, i-titanium - igolide, i-Titanium - molybdenum, nickel - ithusi nokunye.

Amapharamitha

| Imodeli | HW1000 | HW1500 | HW2000 |

| Laser Amandla | 1000W | 1500W | 2000W |

| I-Laser Wavelength | 1080±5 nm | ||

| Umthombo we-Laser | I-Raycus ( MAX/JPT umthombo we-laser ozikhethela wona) | ||

| Imodi yokusebenza | Okuqhubekayo | ||

| Imodi Yokuphuma | I-QBH ejwayelekile | ||

| Welding System | Ikhanda lokushisela le-QILIN eliphathwa ngesandla | ||

| I-wire feeder | I-Auto wire feeder | ||

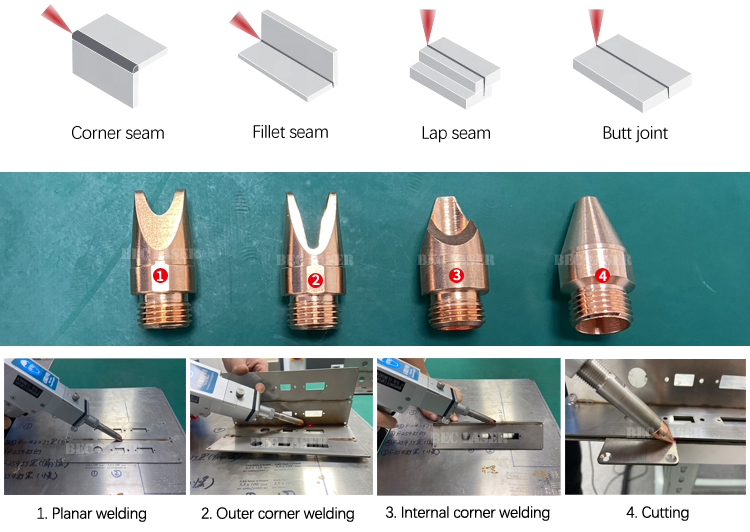

| I-Welding Nozzle | I-Planar, ikhona elingaphandle, ikhona elingaphakathi, umlomo wokusika | ||

| I-Modulation Frequency | 50~50,000Hz | 50~20,000Hz | 1~5,000Hz |

| Ikhwalithi ye-Beam | M2: 1.3 (25μm) | M2: 5-6 (50μm) | M2: 5-7 (50μm) |

| Red Guide Laser Amandla | 0.1 ~ 1 mW | 0.1 ~ 1 mW | 0.5 ~ 1 mW |

| Ukuvikelwa Kwegesi | I-nitrogen noma i-Argon | ||

| Uhlelo Lokupholisa | Uhlelo lokupholisa amanzi | ||

| Izinga Lokushisa Lokusebenza | 0 °C - 35 °C (Akukho ukujiya) | ||

| Amandla Aphelele | ≤6KW | ≤7KW | ≤9KW |

| Imfuneko Yamandla | 220V±10% 50Hz noma 60Hz | 220V±10% 50Hz noma 60Hz | 380V±10% 50Hz noma 60Hz |

| Usayizi Wokupakisha Nesisindo | Umshini: Around 127 * 73 * 129cm, 198KG; I-wire feeder: Around 69 * 59 * 64cm, 48KG. | ||

Amasampula

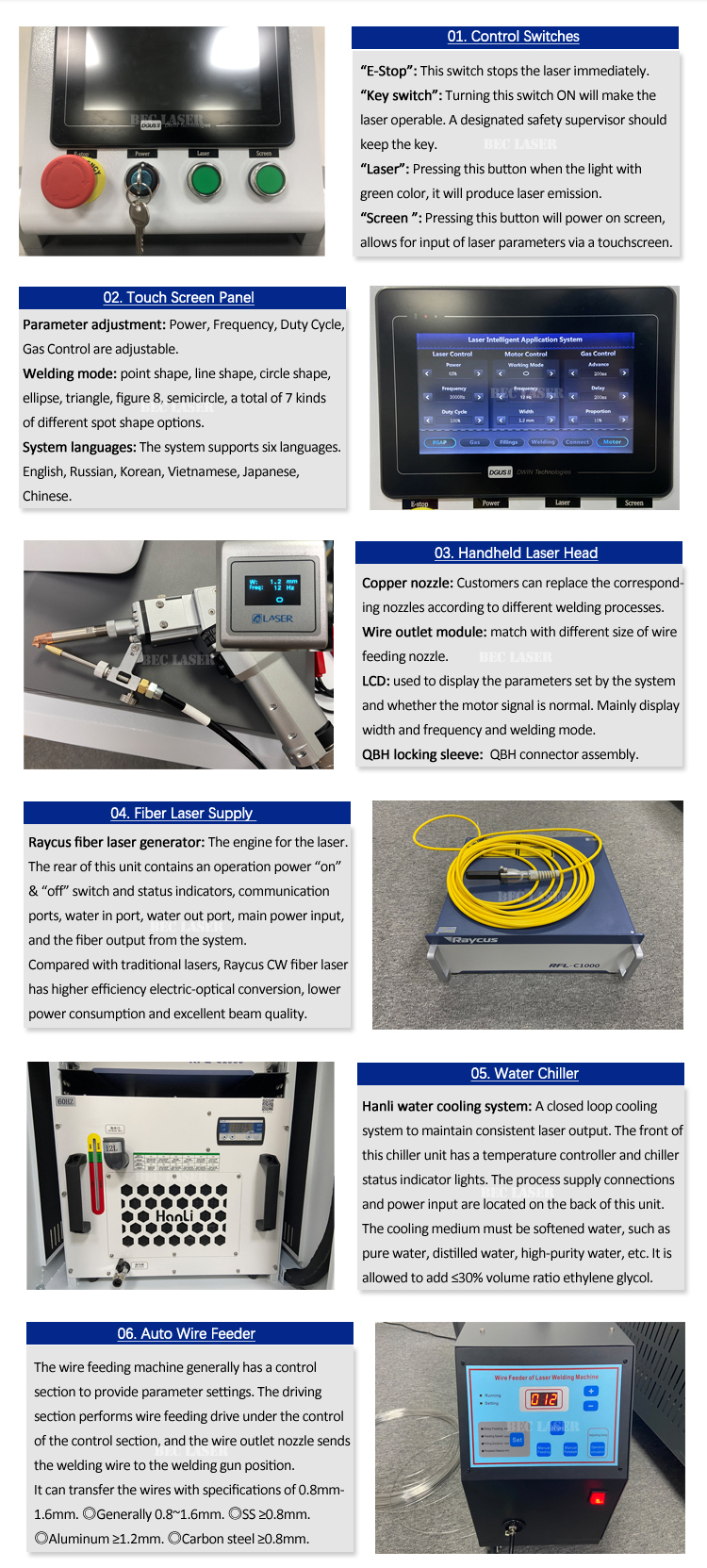

Izakhiwo

Imininingwane